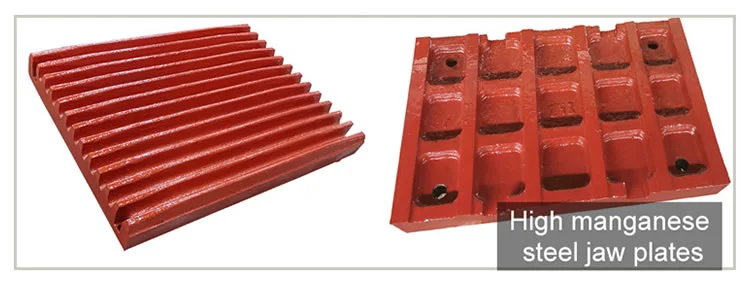

It is widely used in large crushers, mills, machine manufacturing, agricultural machinery, pipe fittings and other industries, and can produce castings of various complex shapes, such as crusher jaw plates, hammers, crusher rotor bodies, engine cylinders, cylinder heads, crankcases, gearboxes, valves, pipe fittings, etc....

Luoyang Zhili New Materials, established in 1992, is one of the leading processing centers for wear-resistant materials in the world, providing high-quality service for wear parts in the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

Zhili New Materials utilizes various processes to produce castings, including sand casting, lost foam casting, metal mold casting, pressure die casting, centrifugal casting, etc. Lost foam casting is the most common method of producing castings. This process offers numerous advantages, low cost, and is chosen by many customers.

Lost foam casting refers to the use of plastic foam molds instead of traditional wood or metal molds. Plastic foam molds are generally made of expandable polystyrene (EPS), expandable polymethyl methacrylate (EPMMA), or their copolymers. During the casting process, the molten metal at high temperature causes the plastic foam mold to vaporize and disappear rapidly. The molten metal replaces the original plastic foam mold and forms a casting after cooling and solidification. After the casting has cooled to a specific temperature, pour the dry sand into the sand box, remove the casting, and clean it to remove sand, burrs, and pouring residue from the surface to obtain the final casting product.

Compared to castings produced by traditional processes, castings produced by the lost foam casting process offer numerous advantages in terms of dimensional accuracy, surface quality, internal defects, mechanical properties, etc., among others, and present the following advantages: they eliminate traditional molding processes, such as demolding, core seating, and box closing, which significantly simplifies the casting process, improves production efficiency, and reduces labor intensity. Furthermore, since the mold is formed integrally, without separation surfaces and cores, the casting exhibits high dimensional accuracy and good surface quality, which can reduce overmetallization and production costs.

Lost foam casting is suitable for producing castings from various metallic materials, including high-manganese steel, high-chromium cast iron, cast steel, aluminum alloy, copper alloy, etc. It is widely used in large crushers, mills, machinery, agricultural machinery, pipe fittings, and other industries, and can produce castings of various complex shapes, such as jaw plates for crushers, hammers, rotor bodies for crushers, engine cylinders, cylinder heads, crankcases, gearboxes, valves, pipe fittings, etc. We have extensive experience in the production of lost foam castings. If needed, please contact us. We offer free design and quotation.

Related articles

Manufacturer of ceramic blow bars, high-chromium ceramic blow bars, blow bars for impact crushers.

As a leading supplier of wear parts for crushers, our company has over 30 years of experience in R&D and production and c...

Zhili New Materials' heat-resistant steel rotary kiln guard plates and chains are preferred by the cement industry. We have a...

It is widely used in large crushers, mills, machine manufacturing, agricultural machinery, pipe fittings and other industries...

In practical applications, the ideal selection of the divider plate material must be tailored to the specific operating condi...

We supply spare parts for hammer crushers, jaw crushers, cone crushers, impact crushers, and vertical mills. As an industry-l...