Flywheel/pulley crusher

Global Sales Custom OEM Design

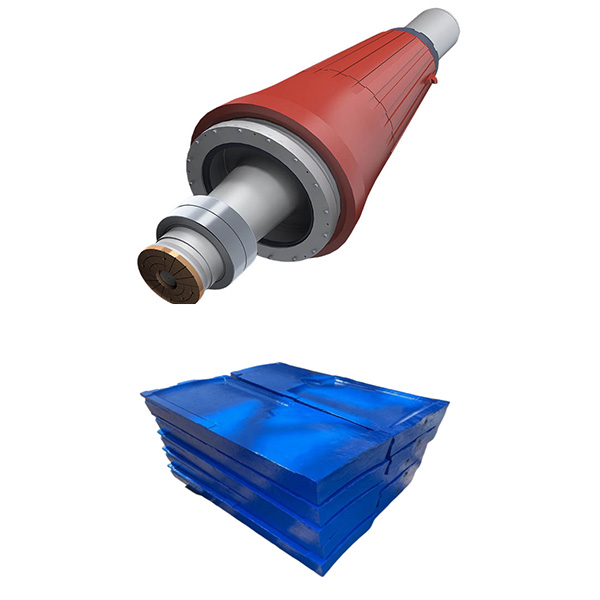

Product Name:Crusher Flywheel/Pulley

Production Process: Casting

Applicable Machines:Jaw crusher, stone crusher, cone crusher, hammer crusher, etc. Applicable Industries: Cement, stone, coal, metal recycling, etc. Suitable Materials: Granite, basalt, limestone, river pebbles, cement clinker, quartz, iron ore, bauxite, salt, brick, coal, etc. Types of Materials: Ductile iron, cast steel, carbon structural steel, etc. example: HT200, HT250, QT450-10, QT500-7

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

4. We offer free quotes, worldwide sales, short delivery cycles, and low prices.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a factory specializing in spare parts for crushers.

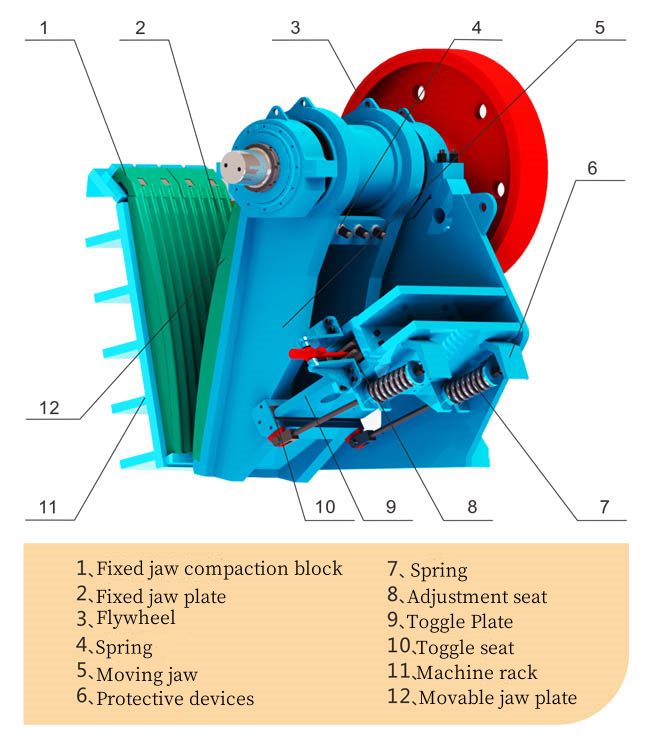

The crusher flywheel is an important component of the crusher. During the crusher's working process, the power source, such as the motor, drives the flywheel to rotate through the transmission device. Because the flywheel has a large mass and moment of inertia, a large amount of kinetic energy is stored during the rotation process. When the crusher's crushing chamber encounters a large block of material or impact load, the energy stored in the flywheel is released to help the crusher overcome the instantaneous resistance and ensure that the crushing work can be carried out stably, continuously, and effectively.

To ensure the stable quality of the crusher flywheel, we rigorously control each link, such as design, material selection, manufacturing, and testing.

According to the environment and working conditions of the crusher, select the appropriate material. For example, in a high-impact and high-wear environment, materials with high strength, high toughness, and good wear resistance should be selected; for flywheels operating in high-temperature environments, the thermal stability and thermal fatigue performance of the materials must be considered. The flywheels we design meet the stringent requirements for moment of inertia, stiffness, strength, and dynamic balance, ensuring that customers can install and use them normally.

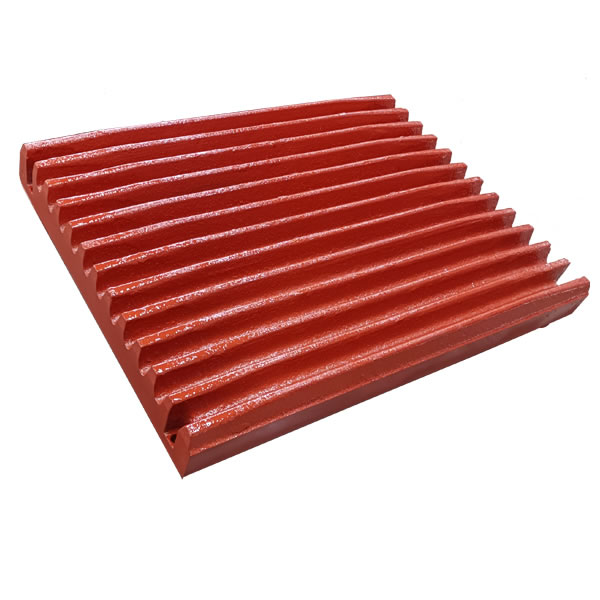

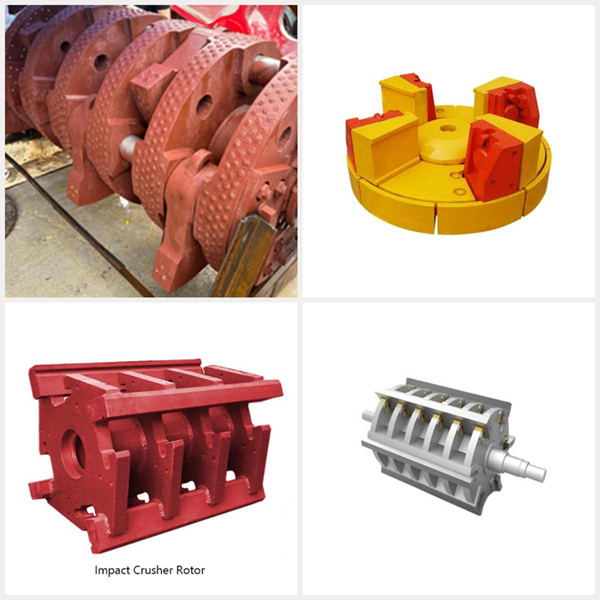

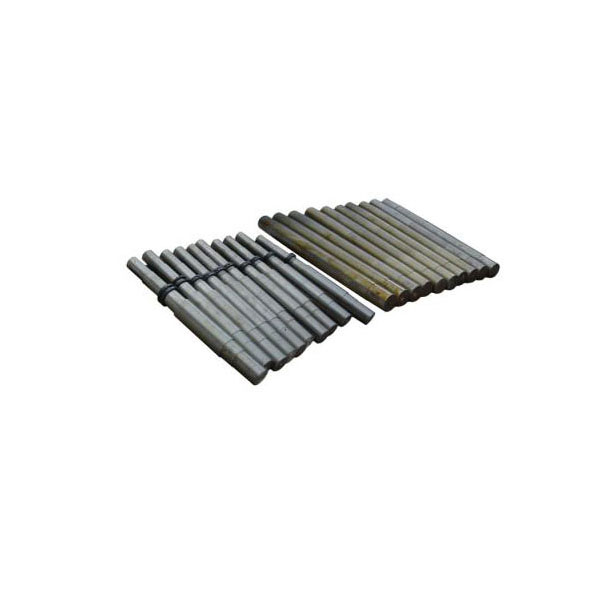

Related Products