Rotary kiln current

Global sales Custom OEM Design

Product Name:Heat-resistant steel chains/Round chains/Oval chains/Rotary furnace chains

Production Process: Casting

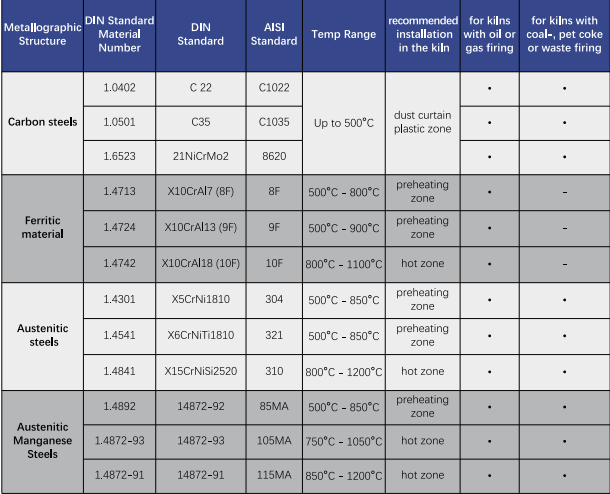

Material Types: Carbon steel, alloy steel, tempered alloy steel, stainless steel, etc.

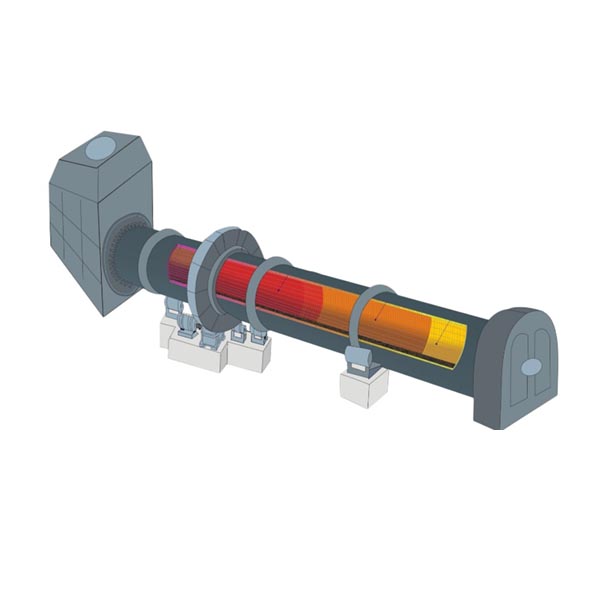

Applicable industries: Cement, metallurgy, chemical industry, architecture, steel industry, paper manufacturing, metallurgy, etc.

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send us an email (info@lyzhili.com), as we are a factory specializing in heat-resistant steel castings.

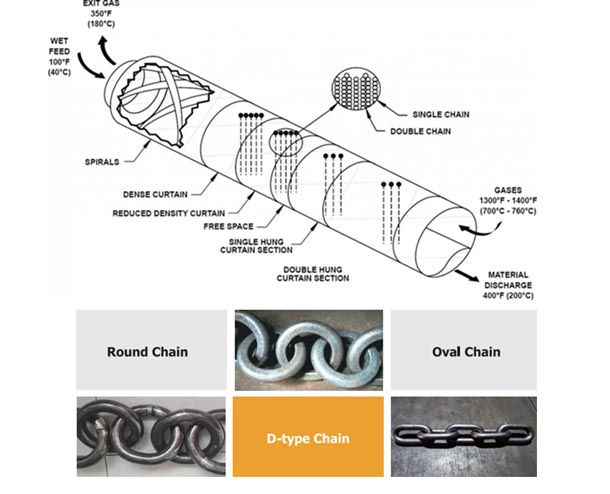

Cement kiln chains mainly include: round kiln chains, oval kiln chains, HEAT-X kiln chains, etc.

Industrial D-rings are made of special high-strength forged steel, combined with heat treatment and welding technology, and are mainly used in coal mines, ships, cement, civil construction and other industries.

Round Link Cast Kiln Chains are a type of Rotary Kiln Chain, mainly used in rotary kilns. Round Link Cast Kiln Chains are more durable than oval chains. Under uniform wear conditions, round rings have a longer service life than oval rings.

Rotary Kiln Chains with Heat Transfer are manufactured in various sizes, ranging from 3/4" to 1-1/4" in diameter.

We have over 35 years of experience in manufacturing rotary kiln chains and other alloy steel products.

Advantages:

1. Patented alloy can extend the lifespan of the chain link;

2. Stable heat resistance, good heat transfer effect;

3. Various materials to meet customer needs.

Related Products