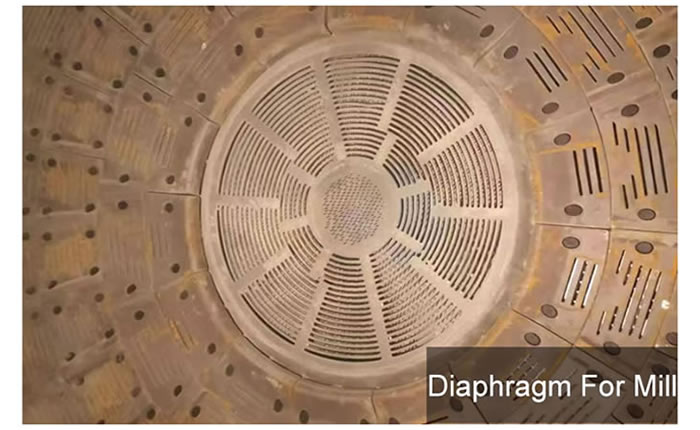

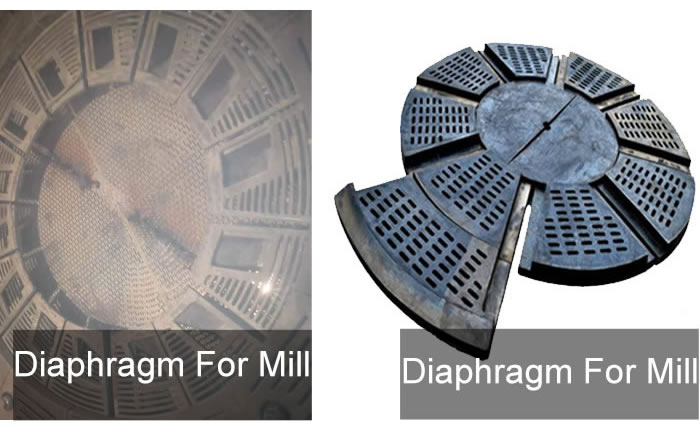

Diaphragm for mill plate

Global sales Custom OEM Design

Product Name: Discharge Device/Diaphragm for Cement Mill/Wear Separator Plate/Intermediate Diaphragm

Production Process: Casting

Applicable Machines: Ball Mill/Semi-Autogenous Mill/Cement Mill

Material Types: High-strength Steel Manganese content, high-chromium cast iron, alloy steel, etc.

Applicable industries: mining, cement plants, coal, steel, etc.

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a custom wear parts factory.

The cylinder is divided into intermediate baffles with two or three grinding silos. The separator plate of the wear chamber has holes smaller than the diameter of the steel balls in the two abrasive cavities, allowing the passage of material and subsequent grinding. Due to the prolonged friction between the steel balls and the materials on both sides of the abrasive silo, the silo panel needs to be highly wear-resistant to reduce the replacement cycle. Some ball mills use double-layer diaphragms to better distinguish the two abrasive cavities and prevent them from collapsing and damaging the body.

Characteristic:

We use suitable alloys and related technological measures to ensure that the surface hardness of the impact bars reaches more than 58HRC, maintaining high hardness and high wear resistance during the wear process.

Technological Process

In the workpiece of the impact bars, we use the directional solidification technique to make the Cr7C3 type carbide perpendicular to the workpiece. The macrohardness and microhardness of the carbide can be improved without reducing the hardness.

Application

Suitable for manufacturing wearable replacement parts with lower impact load and simpler shape.

Chemical component

Grade | Componente químico% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| BTMCr15 | 2.0~3.3 | ≤1.2 | ≤2.0 | 14~18 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr20 | 2.0~3.3 | ≤1.2 | ≤2.0 | 18~23 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23~30 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.10 |

| 1: Allows adding microscale values of V, Ti, Nb, B, and Re, etc. 2: We will select the specific class and component according to the weight, thickness, and size of the impact bars. | |||||||||

Mechanical Property

Grade | Surface hardness | |||||

|---|---|---|---|---|---|---|

Casting condition | Hardened condition | Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| BTMCr15 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr20 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr26 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

1. There is no exact correspondence between Rockwell hardness (HRC) and brine hardness (HB), therefore, both types of hardness values can be used. 2. The hardness in the casting section with a depth of 40% should be less than 92% of the surface hardness. | ||||||

Characteristic

High-manganese steel refers to high-alloy steels containing more than 10% manganese. The main characteristics of high-manganese steel are:

The higher the external compressive stress or impact load, the greater the likelihood of a hardened layer forming, therefore, the greater the wear resistance of the casting;

With the gradual wear of the hardened layer, new hardened layers will continue to form under the influence of external compressive stress or impact loads. Therefore, it is suitable for manufacturing spare parts that are subject to high impact and wear loads for a long time, being widely used in metallurgy, mining, building materials, railways, electric power, coal, and other broken grinding equipment.

Chemical component

| Nota | Chemical component % | |||||

|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | S | P | |

| ZG120Mn13 | 1.05~1.35 | 0.3~0.9 | 11~14 | - | ≤0.06 | ≤0.04 |

| ZG120Mn13Cr2 | 1.05~1.35 | 0.3~0.9 | 11~14 | 1.5~2.5 | ≤0.06 | ≤0.04 |

| ZG120Mn17Cr2 | 1.05~1.35 | 0.3~0.9 | 16~19 | 1.5~2.5 | ≤0.06 | ≤0.04 |

| 1: Allows adding microscale V, Ti, B, and Re, etc. 2: We can produce other types of high manganese steel hammers according to customer needs. | ||||||

Mechanical Property

Grade | Stretch property | Hardness HB | |||

|---|---|---|---|---|---|

| yield strength ReH/Mpa | tensile strength Rm/Mpa | Section elongation% | impact absorbing energyKu2J | ||

| ZG120Mn13 | - | ≥685 | ≥25 | ≥118 | ≤300 |

| ZG120Mn13Cr2 | ≥390 | ≥735 | ≥20 | - | ≤300 |

Characteristic

Alloy steel is an iron-carbon alloy formed by adding an appropriate amount of one or more alloying elements to ordinary carbon steel.

Process Technology

Depending on the different elements added, with appropriate casting and heat treatment processes, high strength, high toughness, high wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, non-magnetic properties, and other related special properties are obtained.

Scope of Application

It is suitable for the production of wear-resistant spare parts with good mechanical strength and good toughness, required for various working conditions, and for major steel structure castings with the necessary dynamic load.

Chemical component

Nota | Chemical component % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | S | P | Ai | |||

| ZG42CrMo | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | 0.80-1.10 | 0.15-0.25 | <0.04 | <0.035 | - | ||

| ZG35CrMo | 0.32~0.40 | 0.17~0.37 | 0.40~0.70 | 0.80~1.10 | 0.15~0.25 | ≤0.035 | ≤0.035 | - | ||

| ZG38CrMoAl | 0.35~0.42 | 0.20~0.45 | 0.30~0.60 | 1.35~1.65 | 0.15~0.25 | ≤0.04 | ≤0.04 | 0.7~1.1 | ||

| ZG40Cr | 0.37~0.45 | 0.17~0.37 | 0.5~0.8 | 0.8~1.1 | - | - | - | - | ||

| ZG30Mn2SiCrMo | 0.25~0.35 | 0.40~0.80 | 1.20~1.60 | 1.35~1.65 | 0.2~0.5 | ≤0.04 | ≤0.04 | - | ||

Mechanical Property

| Grade | tensile strength(Mpa) | yield point(Mpa) | Elongation in cross-section(%) | Section contraction rate(%) | Shock absorption energy(KV2/J) |

|---|---|---|---|---|---|

| ZG42CrMo | ≥1080 | ≥930 | ≥12 | ≥20 | ≥24 |

| ZG35CrMo | ≥985 | ≥835 | ≥12 | ≥20 | ≥24 |

| ZG38CrMoAl | ≥980 | ≥835 | ≥14 | ≥20 | ≥24 |

| ZG40Cr | ≥980 | ≥785 | ≥9 | ≥20 | ≥24 |

| ZG30Mn2SiCrMo | ≥1500 | ≥1300 | ≥3 | - | ≥24 |

Related Products