Vertical mill lining

Global sales Custom OEM Design

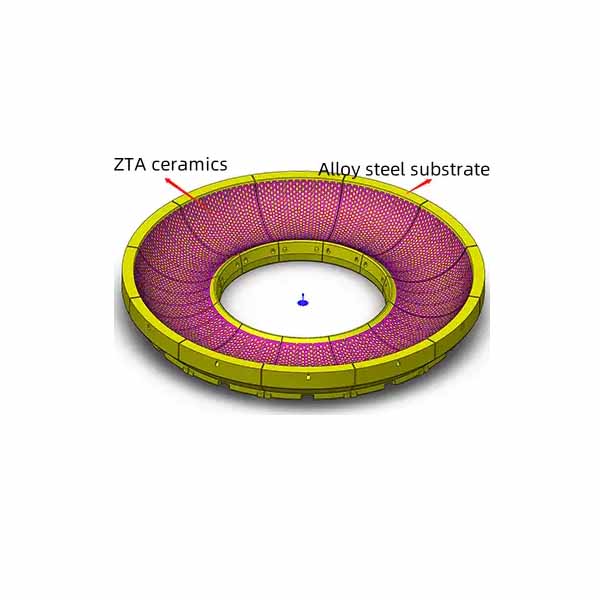

Product Name:Grinding Table/Lining for Vertical Mill

Production Process: Casting

Applicable Machines: Vertical Mill

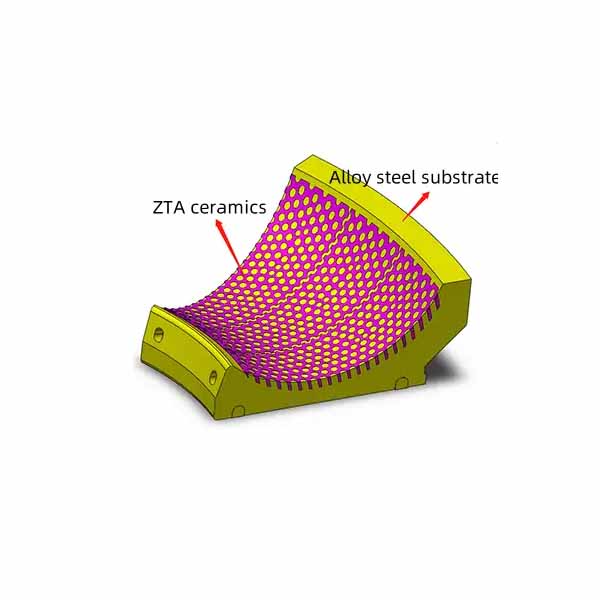

Material Types: High-chromium cast iron, ceramic-metallic composite, high-manganese steel, medium-alloy steel, high-carbon steel bar Manganese content + TiC alloy, etc.

Applicable industries: mining, cement plants, coal, steelmaking, etc.

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a custom wear parts factory.

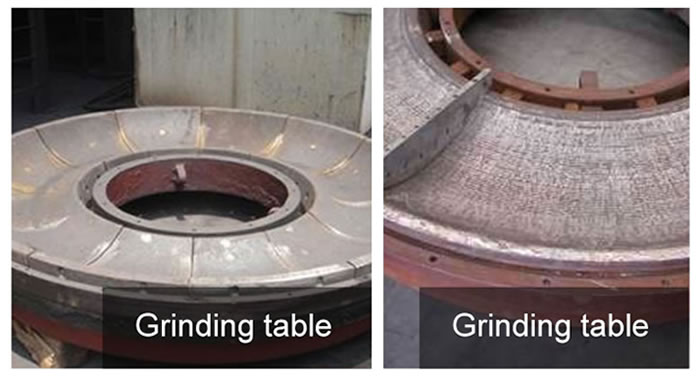

The lining of vertical mills is divided into concave, flat, and bowl types, which correspond to the tire, cone, and cylinder types of the grinding roller, respectively. Concave and flat tables are commonly found on the market.

The linings of vertical mills are made of high-chromium cast iron, ceramic-metallic composite, high-manganese steel, medium-alloy steel, high-manganese steel + TiC alloy bar, etc., and have good wear and corrosion resistance.

Currently, to extend service life and reduce costs, welding rods made of wear-resistant materials are frequently used to coat the surface of the grinding table. This achieves the effect of multiple uses for a single table. The surface layer can adapt to a variety of working conditions, avoiding the need to replace the entire table due to changes in working conditions.

Related Products