Raw material crushing hammer

Global sales Custom OEM Design

Product Name:Raw Material Crusher Hammer

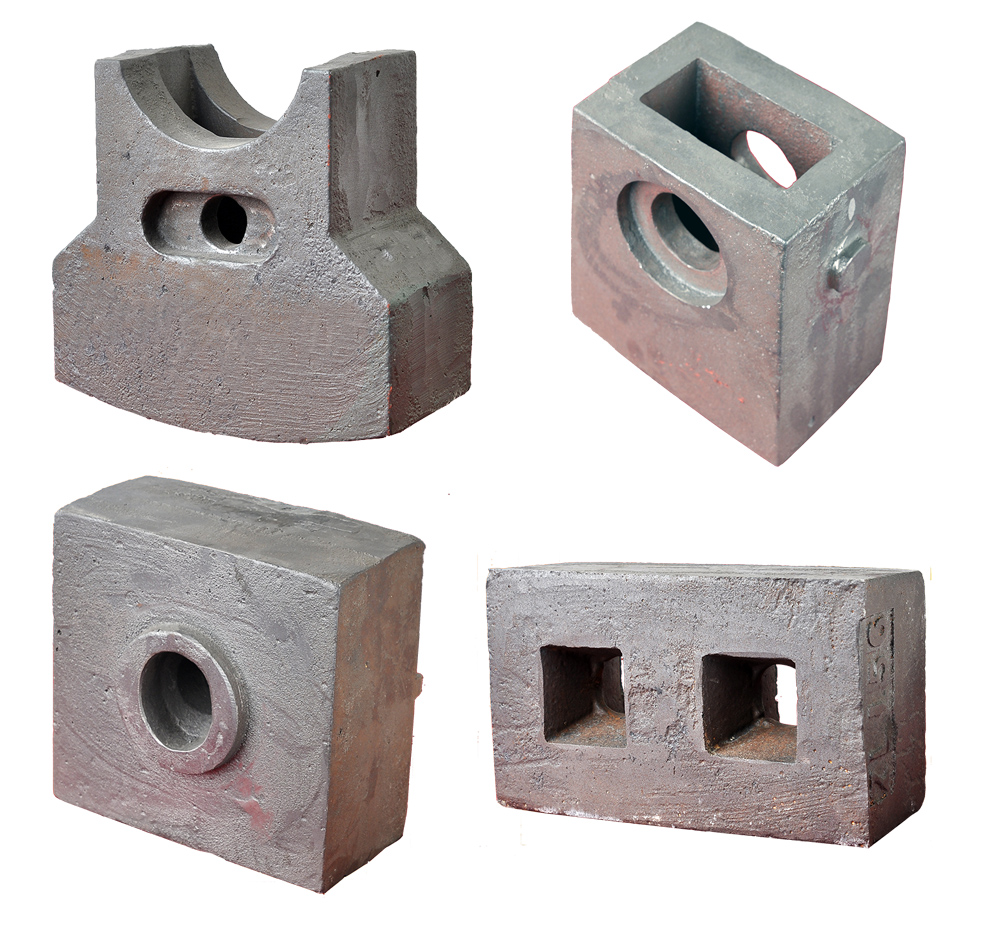

Production Process: Casting

Applicable Machines: Raw Material Crusher

Applicable Materials: Limestone, cobblestone, river pebbles, limestone, gangue, basalt, etc.

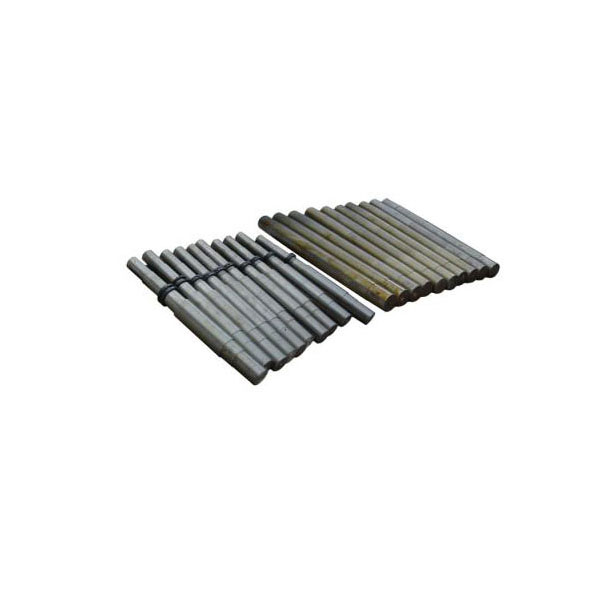

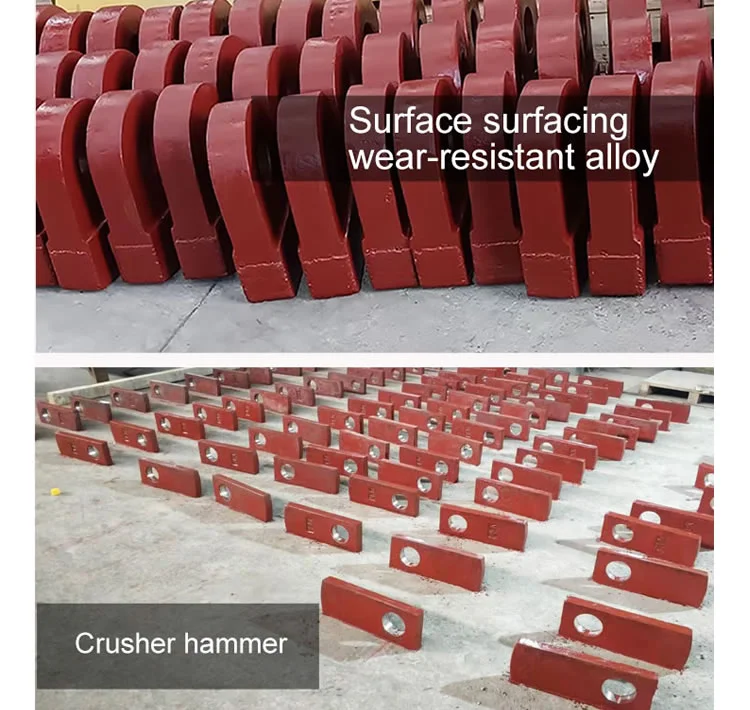

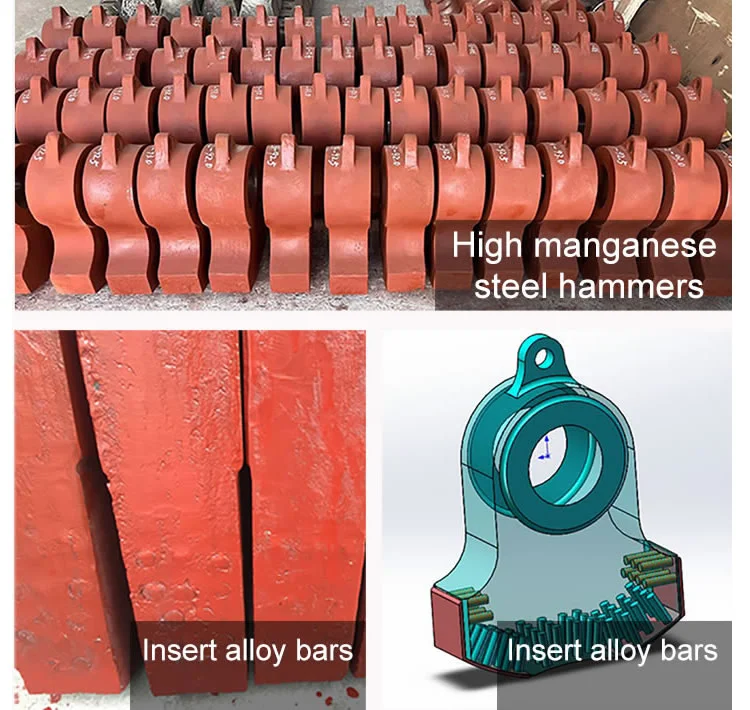

Types of materials: High manganese steel, high manganese steel insert alloy bars, high manganese steel + hardfacing layer, bimetallic composite, high chromium cast iron, alloy steel, etc.

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a factory specializing in spare parts for crushers.

The materials for high-manganese steel hammer heads include tungsten-molybdenum alloy bars with Mn13Cr2, Mn18Cr2, Mn13 or Mn18 inserts and wear-resistant alloys for surface coating.

Applicable working conditions: Suitable for cement plants, quarries and other rocky locations with harsh conditions.

The functional part of the hammer head is made of high-chromium, high-wear-resistant cast iron, and the handle is made of high-tenacity alloy steel.

Features:High wear resistance

Applicable working conditions:Limestone, cement clinker, iron ore, sandstone, coal gangue, basalt and other hard stone crushing areas.

We use appropriate alloys and related technological measures to ensure that the surface hardness of the high-chromium iron hammers reaches more than 58 HRC and, during the wear process, maintains high hardness and high wear resistance.

Applicable working conditions:Suitable for the manufacture of wearable replacement parts with lower impact load and simpler shape.

Related Products