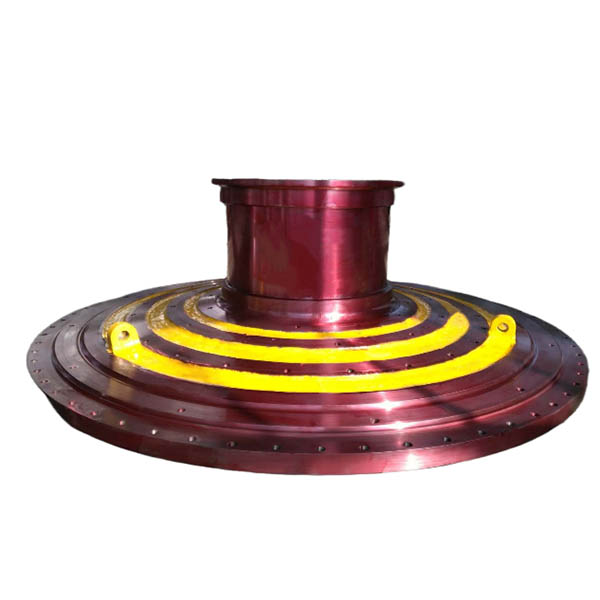

Circular gear/sprocket

Global sales Custom OEM Design

Product Name:Gear for ball mill/circular gear, Gear for rotary kiln/circular gear, Large gear for mill

Production Process: Casting, Forging

Applicable Machines: Ball mill, rotary kiln, etc.

Applicable Industries: Cement, stone, concrete, coal, steel, etc.

Suitable Materials: Granite, basalt, limestone, river pebbles, cement clinker, coal, etc.

Types of materials: 20CrMnTi, 20CrMnMo, 20CrNiMo, 20CrNi2Mo, 12CrNi3, low carbon alloy steel, 40CrNiMo, 38CrMoAl, 25Cr2MoV, 38CrMoAl, etc.

Our services:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, dimensions of spare parts, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

4. We will ensure that the quality of the purchased components is impeccable and that the technical parameters fully meet national standards.

5. We provide free quotations, worldwide sales, short delivery times, and low prices.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to us (info@lyzhili.com), as we are a custom manufacturer of spare parts for crushers.

Generally, we use forged parts, steel bars, or cast parts with good toughness and ease of machining, often using forged parts.

First, the raw part is normalized to improve its machinability and roughing.

In the semi-finishing process, the gears are basically formed and then processed to obtain their mechanical properties. According to the requirements of the working conditions and the materials used, tempering and hardening, carburizing, and high-frequency induction on the tooth surface are used. Thermal hardening, nitriding, and other processes allow obtaining the mechanical properties that must be obtained under different working conditions.

Finally, the gears need precision machining.

Steel grades for different working conditions

Medium hardness gears (HB220-320): 40Cr, 42CrMo, 40CrNiMo, 38CrMoAl and other medium carbon alloy steels. Hardened gears (HRc56-62): 20CrMnTi, 20CrMnMo, 20CrNiMo, 20CrNi2Mo, 12CrNi3, low carbon alloy steels.

Nitriding gears: 25Cr2MoV, 38CrMoAl.

For large diameter teeth (D> 400-600 mm), cast steel tooth blanks cannot be forged; instead, cast steel tooth blanks can be used, generally ZG45, ZG 40Cr, ZG 42CrMo, ZG 40CrNiMo, ZG 38CrMoAl and other medium carbon alloy steels. The composition of the cast steel is equivalent to the chemical composition of the forged steel, with only an increase in Si content to 0.60-0.80%.

Related Products