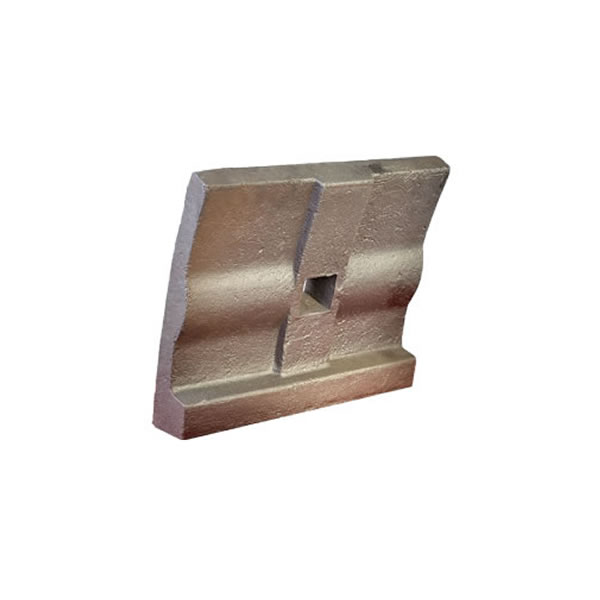

Eccentric shafts

Global sales Custom OEM Design

Product Name: Jaw Crusher Shaft/Eccentric Shafts/Crusher Shaft

Production Process: Casting

Applicable Machines: Jaw Crusher

Applicable Industries: Cement, Stone, Coal, Steel, Metal Recycling, etc.

Types of materials: medium alloy steel

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a factory specializing in spare parts for crushers.

The eccentric shaft is the main shaft of the jaw crusher and is subject to significant bending and twisting. The eccentric shaft is equipped with a pulley at one end and a flywheel at the other.

The jaw crusher is subject to eccentric shaft wear problems. The shaft neck and the shaft neck of the eccentric section suffer severe wear, the shaft is excessively bent, and fatigue fracture causes eccentric shaft wear. We can supply eccentric shafts of suitable materials, according to the working conditions, to ensure the normal operational efficiency of the crusher. Medium Alloy Steel Material Characteristics Structural alloy cast steel is an iron-carbon alloy composed by adding an appropriate amount of one or more alloying elements to ordinary carbon steel. Process Technology Depending on the different elements added, and with appropriate casting and heat treatment processes, high strength, high toughness, high wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, non-magnetic properties, and other related special properties can be obtained. Structural alloy cast steel is a composite iron-carbon alloy formed by adding an appropriate amount of one or more alloying elements to ordinary carbon steel. Process Technology Depending on the different elements added, and with appropriate casting and heat treatment processes, high strength, high toughness, high wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, non-magnetic properties, and other related special properties can be obtained.

Scope of application

It is suitable for the manufacture of wear-resistant spare parts with good comprehensive mechanical properties, with the strength and toughness required by various working conditions, as well as castings for main steel structures that need to withstand dynamic loads.

Chemical component

Notice | Chemical component | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | S | P | Ai | |||

| ZG42CrMo | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | 0.80-1.10 | 0.15-0.25 | <0.04 | <0.035 | - | ||

| ZG35CrMo | 0.32~0.40 | 0.17~0.37 | 0.40~0.70 | 0.80~1.10 | 0.15~0.25 | ≤0.035 | ≤0.035 | - | ||

| ZG38CrMoAl | 0.35~0.42 | 0.20~0.45 | 0.30~0.60 | 1.35~1.65 | 0.15~0.25 | ≤0.04 | ≤0.04 | 0.7~1.1 | ||

| ZG40Cr | 0.37~0.45 | 0.17~0.37 | 0.5~0.8 | 0.8~1.1 | - | - | - | - | ||

| ZG30Mn2SiCrMo | 0.25~0.35 | 0.40~0.80 | 1.20~1.60 | 1.35~1.65 | 0.2~0.5 | ≤0.04 | ≤0.04 | - | ||

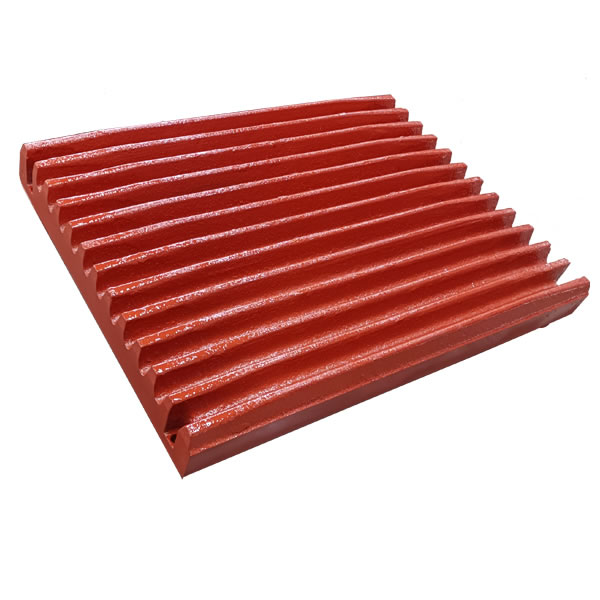

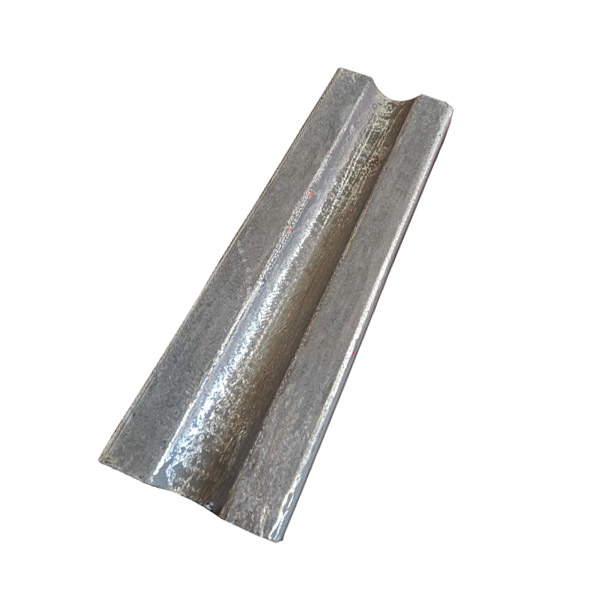

Related Products