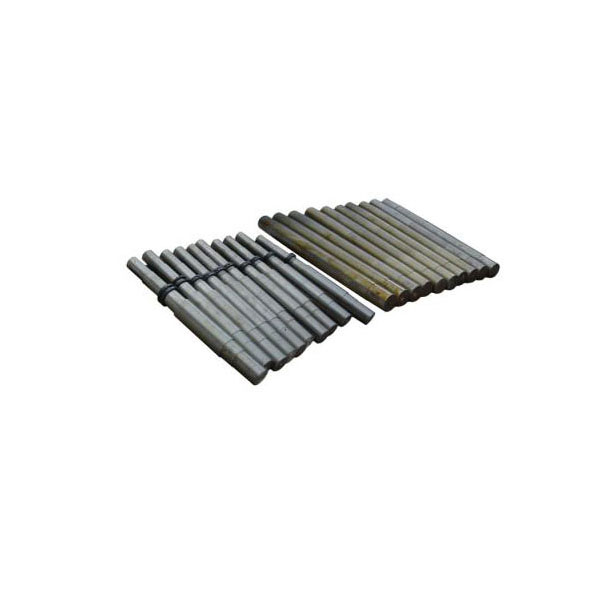

Hammer shaft

Global sales Custom OEM Design

Product Name: Hammer Crusher Shaft

Production Process: Casting

Applicable Machines: Hammer Crusher

Applicable Materials: Limestone, cobblestone, river pebbles, bluestone, gangue, basalt, etc.

Types of materials: Medium alloy steel

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a factory specializing in spare parts for crushers.

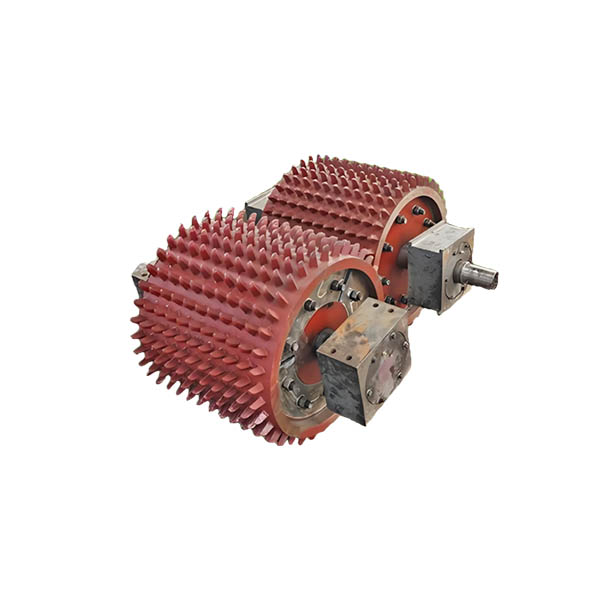

The hammer shaft is mounted on the rotor and supports several hammers horizontally. During crusher operation, it withstands the mutual friction between the hammer rings. It is also a wear part of the crusher, and the quality of the hammer also significantly affects the crushing. The normal operation of the machine. According to the hammer hardness, we can supply the hammer shaft of the corresponding material to ensure the normal operational efficiency of the crusher.

Medium Alloy Steel

Characteristic

Alloy cast steel is an iron-carbon alloy formed by adding an appropriate amount of one or more alloying elements based on ordinary carbon steel.

Process Technology

Depending on the different elements added, with appropriate casting and heat treatment processes, high strength, high toughness, high wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, non-magnetic properties, and other related special properties are obtained.

Scope of Application

It is suitable for the production of wear-resistant spare parts with good mechanical strength and toughness, required for various working conditions, and for the casting of main steel structures with the necessary dynamic load.

Chemical component

Grade | Chemical component % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | S | P | Ai | |||

| ZG42CrMo | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | 0.80-1.10 | 0.15-0.25 | <0.04 | <0.035 | - | ||

| ZG35CrMo | 0.32~0.40 | 0.17~0.37 | 0.40~0.70 | 0.80~1.10 | 0.15~0.25 | ≤0.035 | ≤0.035 | - | ||

| ZG38CrMoAl | 0.35~0.42 | 0.20~0.45 | 0.30~0.60 | 1.35~1.65 | 0.15~0.25 | ≤0.04 | ≤0.04 | 0.7~1.1 | ||

| ZG40Cr | 0.37~0.45 | 0.17~0.37 | 0.5~0.8 | 0.8~1.1 | - | - | - | - | ||

| ZG30Mn2SiCrMo | 0.25~0.35 | 0.40~0.80 | 1.20~1.60 | 1.35~1.65 | 0.2~0.5 | ≤0.04 | ≤0.04 | - | ||

Mechanical Property

| Nota | tensile strengtho (Mpa) | yield point(Mpa) | Elongation in cross-section(%) | reduction of cross-sectional area(%) | Shock absorption energy(KV2/J) |

|---|---|---|---|---|---|

| ZG42CrMo | ≥1080 | ≥930 | ≥12 | ≥20 | ≥24 |

| ZG35CrMo | ≥985 | ≥835 | ≥12 | ≥20 | ≥24 |

| ZG38CrMoAl | ≥980 | ≥835 | ≥14 | ≥20 | ≥24 |

| ZG40Cr | ≥980 | ≥785 | ≥9 | ≥20 | ≥24 |

| ZG30Mn2SiCrMo | ≥1500 | ≥1300 | ≥3 | - | ≥24 |

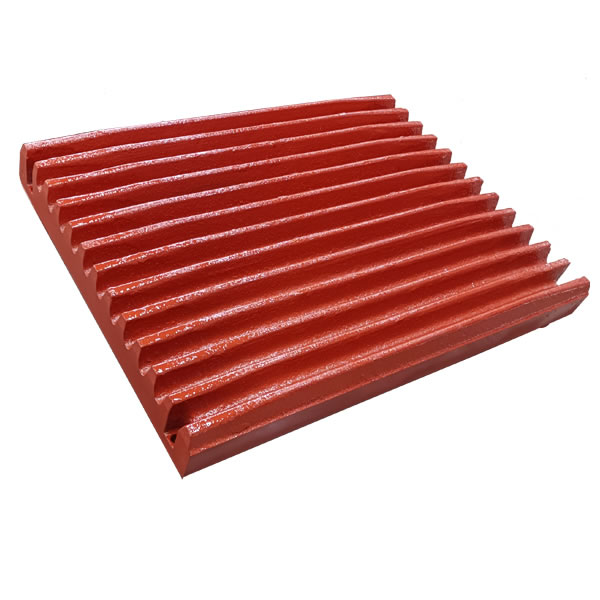

Related Products