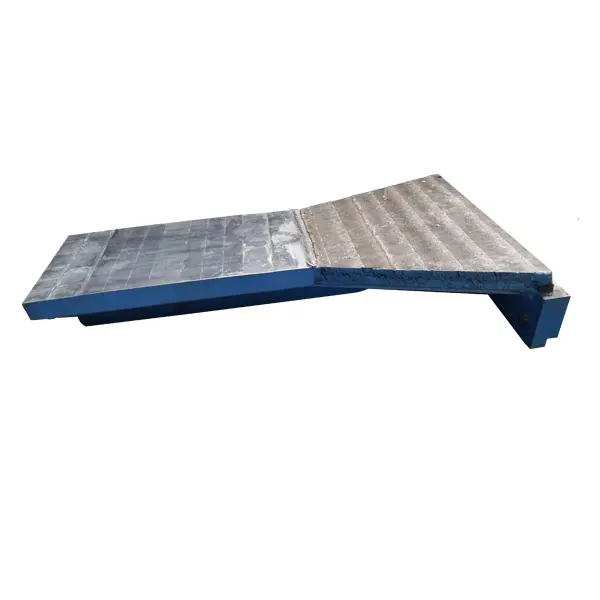

Welding roller for alloy pin surface

Global sales Custom OEM Design

Product Name: Extrusion Roll for Roller Press/Roller Sleeve with Shaft/Rigid Coating Roll

Production Process: Casting + Coating

Applicable Machines: Roller Press

Material Types: Alloy Steel (High Manganese Steel) + Titanium carbide/tungsten carbide (pin) + coating;

Applicable Industries:Cement, chemicals, electricity, metallurgy, building materials, refractory materials

Suitable Materials:Limestone, slag, coke, coal and other materials

Our Service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a factory specializing in spare parts for roller presses.

The roller material is mainly composed of Cr, Mo, V, W, Nb, and other elements. The wear-resistant layer is placed on the outermost layer of the roller sleeve by centrifugal casting. The surface pattern is formed by casting.

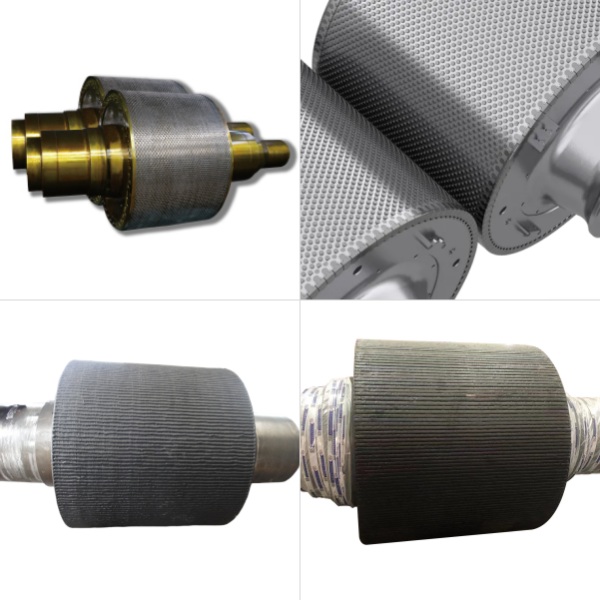

The roller base material is mainly alloy steel + titanium carbide/tungsten carbide (pin), and the surface is welded with welding wire to form a wear-resistant layer.

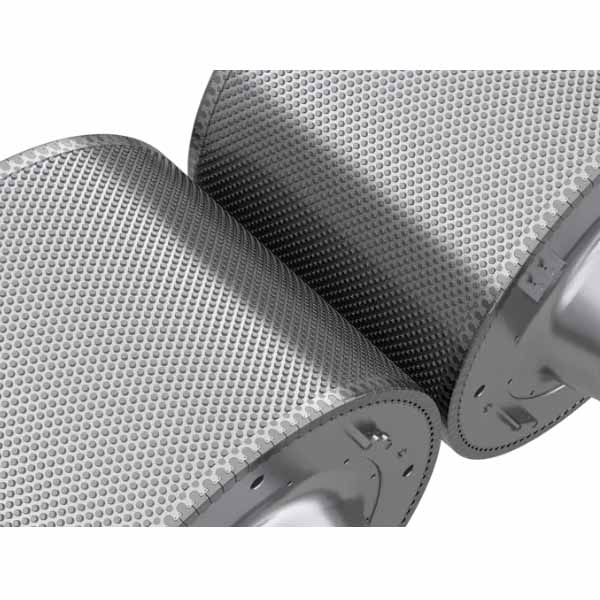

The welding roller for alloy pin coating consists of a roller shaft, a special alloy compound roller sleeve, and wear-resistant carbide pins. The extrusion roll of the roller press for alloy pin coating has the following characteristics:

1. The base metal is high-strength, high-toughness cast steel, which can be welded;

2. The corresponding alloy pins can be selected according to the working conditions. The wear resistance of the alloy pins is good, comparable to that of ceramics, and they can be welded;

3. In case of flaking of the alloy pins under abnormal conditions, they can be replaced by overlapping, which is practical and quick;

4. The alloy pin creates a bonding effect in the embedded welding structure, further improving the strength of the alloy pin and the surface layer. Abrasion and reliability;

5. The surface of the grinding roll exhibits good resistance to peeling and maintains its integrity; the integrity of the roll surface can be guaranteed when foreign materials enter. Restore size quickly.

The vertical mill roll is designed according to the working conditions and the wear resistance curve of the product.

Powder metallurgy technology is used to add pins (material: titanium carbide/tungsten carbide) to the wear area, combined with coating technology. Special welding materials are used to form an embedded welding structure and a metallurgical combination to improve the product's wear resistance, service life, and lifespan, as well as achieving regenerative repair to increase the product's service life.

These rolls are suitable for extreme working conditions in adverse environments and can replace ceramic rolls currently on the market.

Characteristics of different types of vertical mill rollers

Item | Hardfacing roller | Ceramic roller | YDFH Roller |

shaping method | hardfacing | Inlay casting | Inlay welding |

Wearing layer thickness | 40~100 | 40~60 | 40~60 |

Main hard phase of hard surface | NbC, Cr7C3,VC,MoC And so on | ZTA Ceramic | TiC、NbC、Cr7C3、VC、MoC and so on |

Repair-ability | No | No | Can repair 3-5 times |

Roller surface integrity | Restorable to original size | Unrecoverable | Restorable to original size |

Roller Servicing life under Typical working condition | 8000 hours | 16000 hours | 15000-20000 hours |

Cost performance | High under normal working condition | Low | High under under harsh Working conditions |

Notes: Introduction to the vertical mill roll for welding alloy stud surfaces (technical code: YDFH)

Related Products