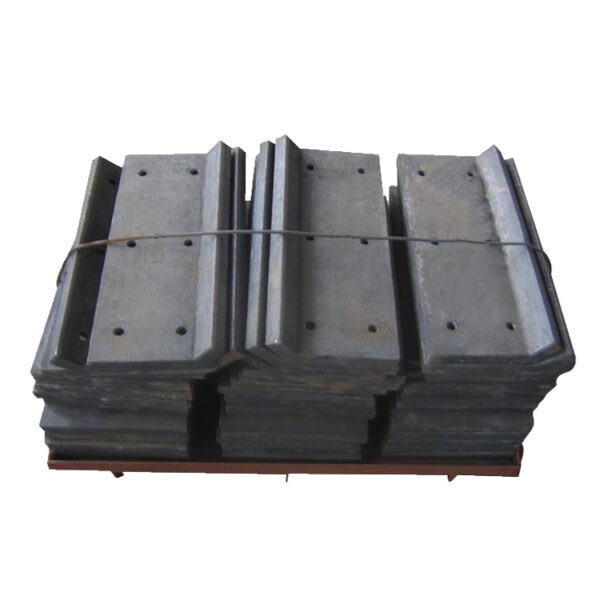

Wear-resistant lining plates for gutters

Global Sales OEM Custom Design

Product Name: Anti-wear coating plates for gutters

Production Process: Casting

Material Types: High manganese steel (Mn13Cr2/Mn18Cr2), high chromium cast iron, ceramic, rubber, bimetallic, ceramic rubber composite, etc.

Applicable industries: mining, cement plants, coal, steelmaking, etc.

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send us an email (info@lyzhili.com), as we are a custom manufacturer of spare parts for crushers.

The chute lining is a wear-resistant protective layer installed on the inner surface of the material conveying chute and is an essential wear-resistant component of the material conveying system.

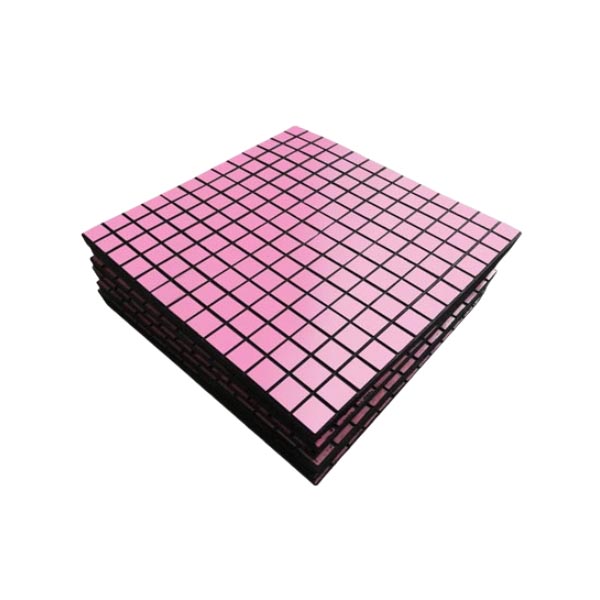

Lining materials mainly include: metal (Mn13Cr2, high-chromium cast iron, wear-resistant alloy steel), non-metallic (ceramic, rubber), composite materials, etc.

The main materials of the lining panels we produce are:

1. The cement clinker cooler chute is mainly made of high-temperature resistant alloy lining;

2. The coal powder conveying chute uses antistatic ceramic lining;

3. The ore beneficiation plant classification chute can use corrugated rubber lining;

4. Ceramic metal composite lining for crusher discharge chute.

We can recommend reasonable materials to customers based on working conditions, and we can also customize production according to customer drawings and requirements.

Tank wear liners are widely used in mining, power generation, cement, dredging, steel production, waste treatment, glass production, and pulp and paper industries.

Related Products