Cone crusher shaft

Global sales Custom OEM Design

Product Name: Cone Crusher Shaft/Cone Crusher Eccentric Shaft/Cone Crusher Main Shaft

Production Process: Forging (hot forging, free forging, die forging)

Applicable Machines: Cone Crusher

Applicable industries:Cement, metallurgy, civil construction, road construction, chemical and phosphate industry, etc.

Types of materials:alloy steel, stainless steel, carbon steel

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a factory specializing in spare parts for crushers.

Suitable for medium or fine crushing of hard and semi-hard rocks and ores, such as iron ore, copper ore, limestone, quartz, granite, gravel, etc.

The selection of the main shaft material requires not only high strength performance but also good toughness, both of which are indispensable. The cone crusher main shaft we produce is made of high-quality alloy steel, such as 40Cr, etc., and is manufactured through multiple processes, such as machining and heat treatment, so that the main shaft has high toughness and strength.

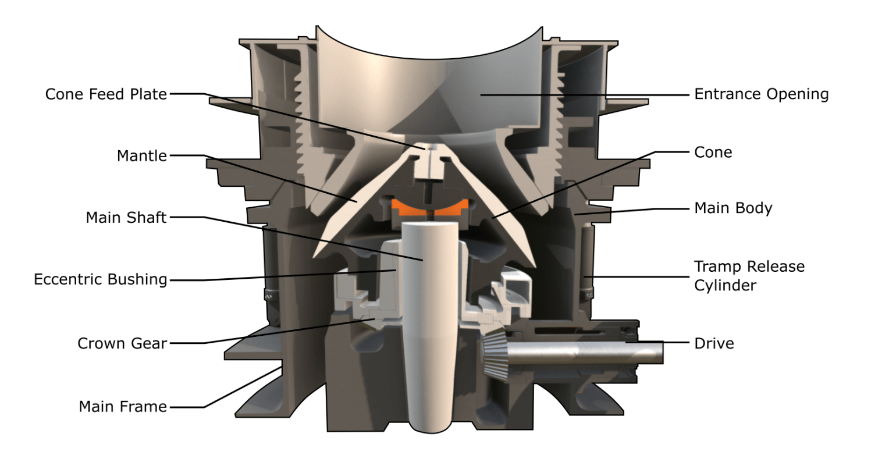

The cone crusher main shaft plays a fundamental role in power transmission and crushing wall support, which directly affects the crushing process and the overall performance of the cone crusher. Regular inspections and maintenance are essential to achieve optimal main shaft performance. Monitor wear and replace worn or damaged main shafts in a timely manner to maintain efficient crushing. This can maximize the efficiency and lifespan of the cone crusher. In a cone crusher, the drive shaft, also known as the countershaft, is an essential component responsible for transmitting the rotational motion and power from the crusher's drive system to the crushing cone. It is located below the mantle and cone assembly.

As the drive system rotates the drive shaft, the rotational motion is transmitted to the crushing cone, which is fixed to the upper end of the drive shaft. The rotation of the crushing cone creates the crushing action in the cone crusher, where the incoming feed material is crushed against the concave liner or vessel.

Related Products