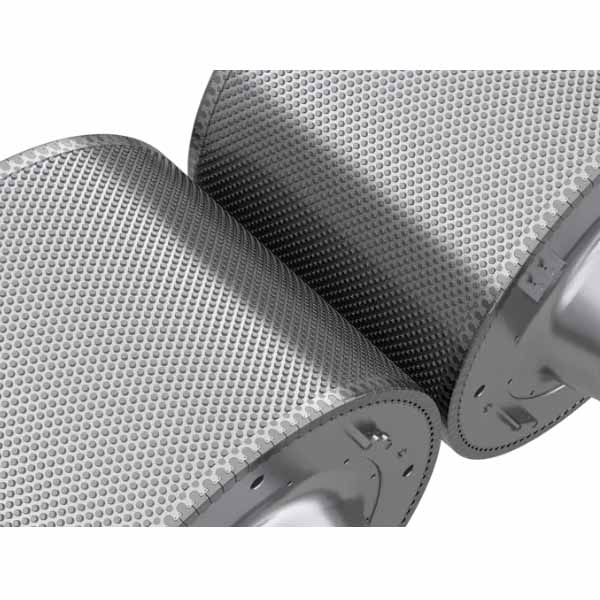

HPGR Stu Rollers/Tires

Global sales Custom OEM Design

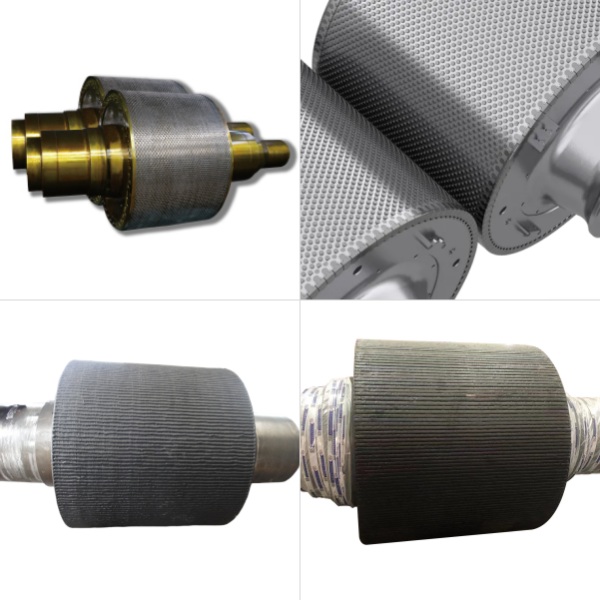

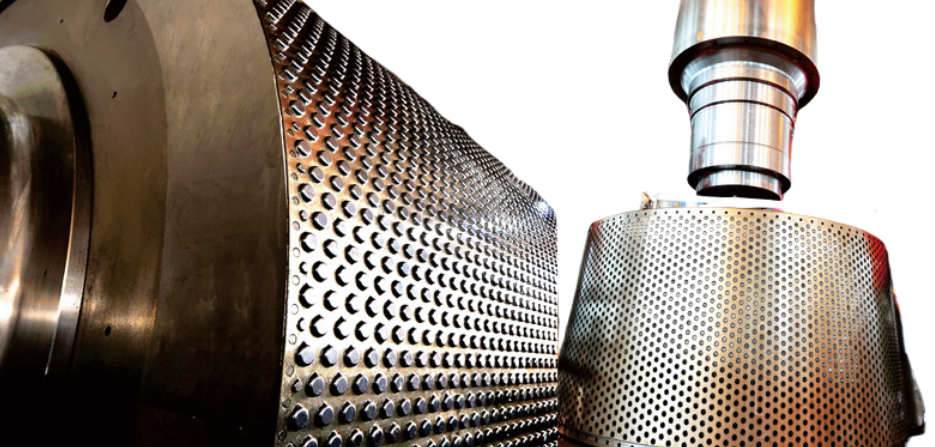

Product Name: HPGR Grinding Rolls / Tires / Pin Roller

Production Process: Forging

Applicable Machines: Roller Press, HPGR

Types of materials: Alloy steel (high manganese steel) + Tungsten carbide (pin)

Applicable industries: Cement, chemicals, electricity, metallurgy, building materials, refractory materials

Suitable Materials: Cement, limestone, slag, coke, coal, and other materials

Our Service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a factory specializing in spare parts for roller presses.

HPGR pin rollers offer advanced wear protection and durability for a variety of retreading applications.

By customizing the pin grade and design to meet specific application needs, it's possible to ensure pins are used effectively and not wasted within a predefined maintenance schedule. Applying different pin hardnesses across the tire width mitigates uneven wear, ensuring effective size reduction over the roller's lifespan.

Features and Benefits:

Long Tire Life

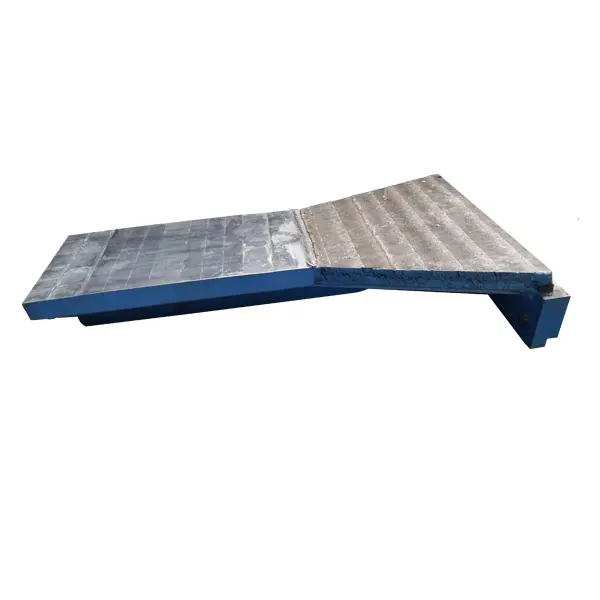

Our pin installation process ensures repeatable quality and grinding roller performance. High-pressure grinding rollers guarantee long service life with edge blocks designed to last and stay in place at all times. Tires can be removed from the shafts and replaced at the end of their service life.

Superior Wear Resistance

The HPGR Stu Rollers tire design combines years of material development and pin design optimization to deliver best-in-class performance. The pin-tipped tire profile allows for the formation of a strong protective mineral layer, improving grinding performance and service life.

High Product Quality with Lower Operating Costs

The unique length-to-diameter ratio of the grinding rolls provides high product quality, minimizes recirculation, and reduces operating costs. Our smaller roll diameter optimizes operating clearance, fully penetrating the pressure through it to exceed the compressive strength of the ore.

In addition, the spring-loaded sidewall system provides excellent sealing, which reduces wear associated with different feeding conditions.

Related Products