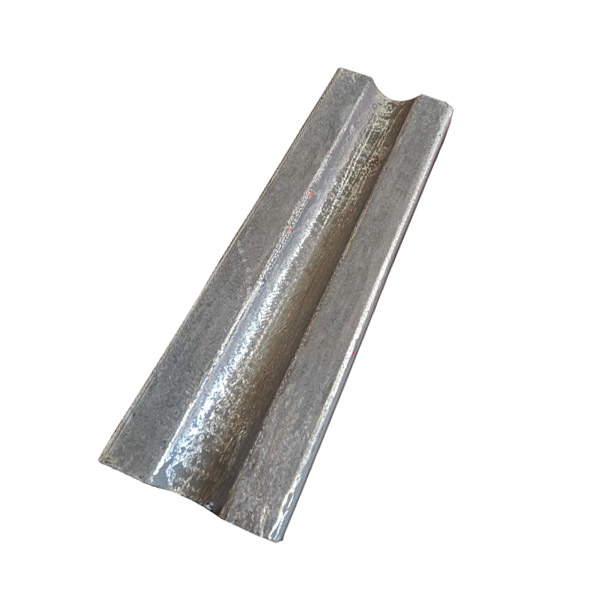

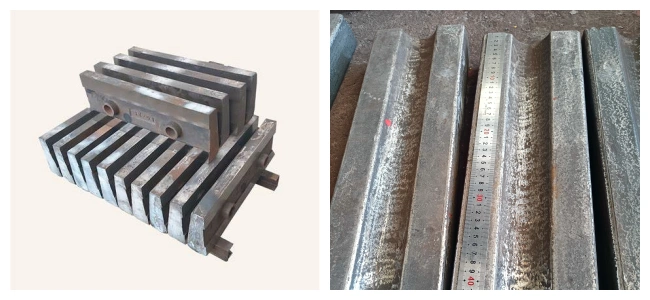

Impact Plates/Impact Blocks

Global sales Custom OEM Design

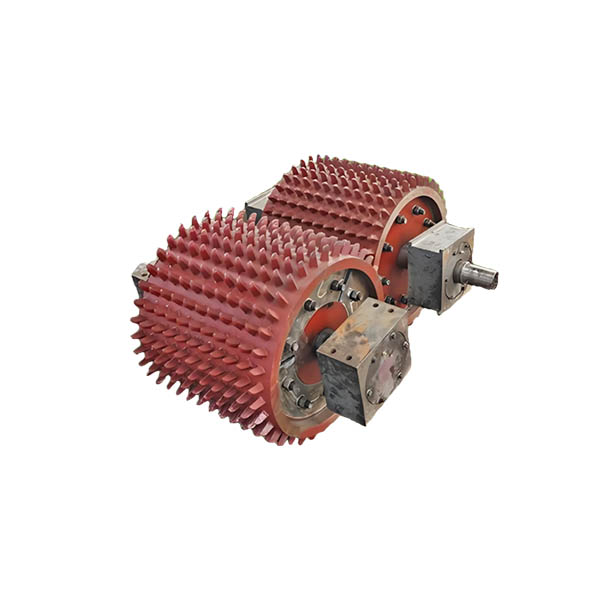

Product Name: Impact Plates, Impact Block, Impact Crusher Parts

Production Process: Casting

Applicable Machines: Various models of impact crushers

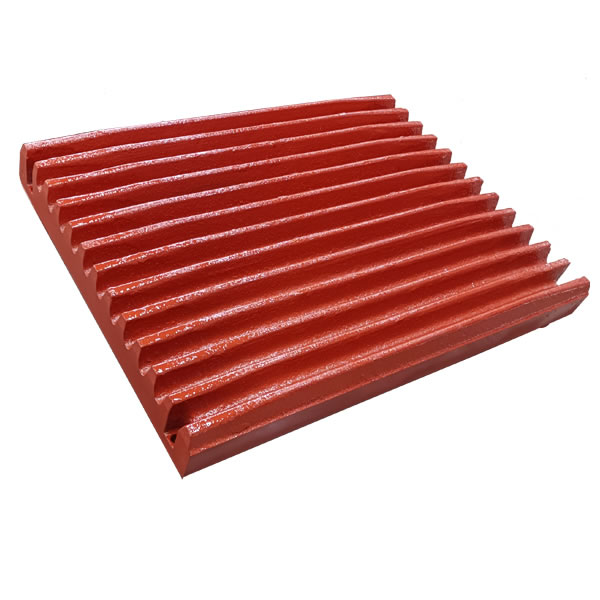

Material Types: High manganese steel (Mn13Cr2/Mn18Cr2), high manganese alloy steel bars, bimetallic composite, high chromium cast iron, alloy steel, etc.

Applicable industries: mining, cement plants, coal, steelmaking, etc.

Applicable materials: river pebbles, rocks, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, etc.

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send us an email (info@lyzhili.com), as we are a factory specializing in spare parts for crushers.

The impact plate is one of the main wear parts of the impact crusher. Its function is to withstand the impact of the material torn off by the plate hammer, so that the material is broken by the impact. Therefore, the surface of the liner is in a complex state of stress. The returning material at high speed exerts a huge impact force on the surface of the impact plate, resulting in chiseling, cutting, impact, and extrusion cavities. This is the main form of wear on the impact plate.

The impact plate is cast with new, wear-resistant material, and is installed and replaced in specific locations according to the wear law of the impact plate and the degree of wear of each part, which more than doubles its service life.

Common impact plates are divided into: dashed line impact plates and arc impact plates. Users can choose the appropriate impact plate according to their working conditions.

Why choose us?

Precise dimensions

The impact plate and other crusher wear parts are manufactured according to the crusher drawings or serial numbers to ensure compatibility with the original machine.

High abrasion resistance

Due to advanced manufacturing technology, the impact plates exhibit high wear resistance, extending their service life.

Reduced downtime

By using a Zhili New Materials impact plate, crusher downtime is effectively reduced. There is less maintenance work to be done.

Rigorous production process

The production process is rigorously controlled to meet international standards.

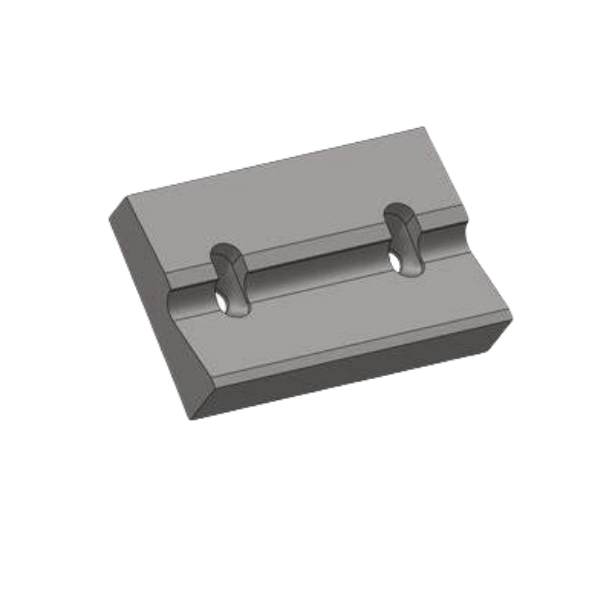

The impact block is one of the main parts of the impact crusher. It is as important as the impact bar, which can protect the machine and reduce wear. Adopting an impact block with high wear and impact resistance can not only extend the service life of the impact crusher, but also increase its production capacity.

Related Products