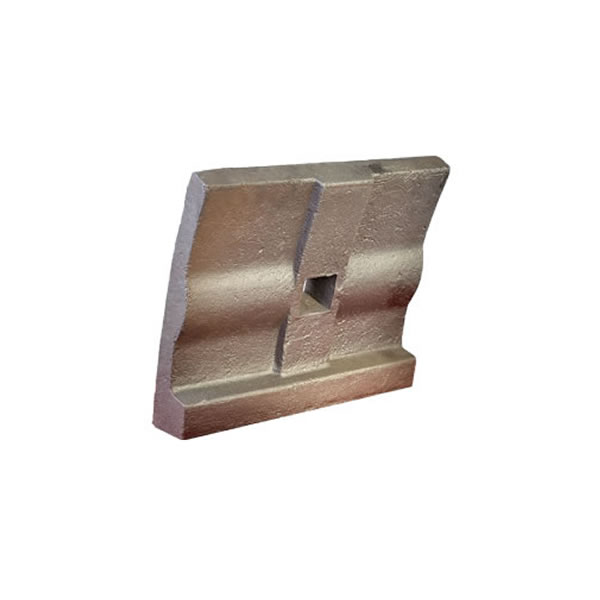

Cheek plate/alternating plate

Global sales Custom OEM Design

Product Name:Support Plate/Joint Plate for Jaw Crusher

Production Process: Casting

Applicable Machines: Jaw Crushers

Material Types: Medium Manganese Steel (Mn8), High Manganese Steel (Mn13-2, Mn13-3, Mn13Cr2), nodular cast iron, etc.

Applicable industries: mining, cement plants, coal, steelmaking, etc.

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a factory specializing in spare parts for crushers.

Jaw Crusher Face Plate

A wide range of high-quality cast face plates for jaw crushers is available for all brands of jaw crushers. Our jaw crusher face plates are cast with the most wear-resistant grades, with the hardest composition for maximum wear resistance. We offer a wide range of grades and surface finishes to best suit your crushing needs.

Features and Benefits:

The product can be infused with tungsten carbide for longer service life;

Installed with a surface wear hardness of 90 Rockwell A;

Reduced crusher downtime and fewer side plate replacements;

Available for the most popular jaw crusher models;

Custom designs to meet specific customer needs or wear conditions.

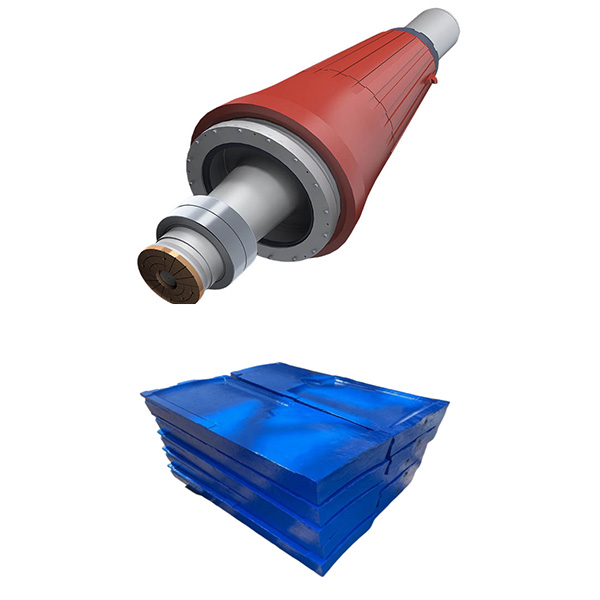

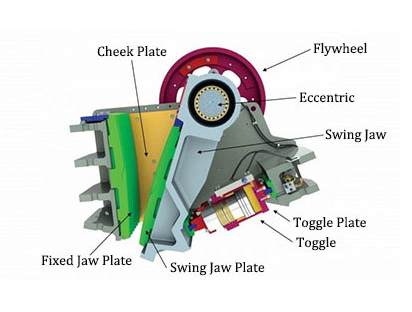

Jaw crusher structure diagram

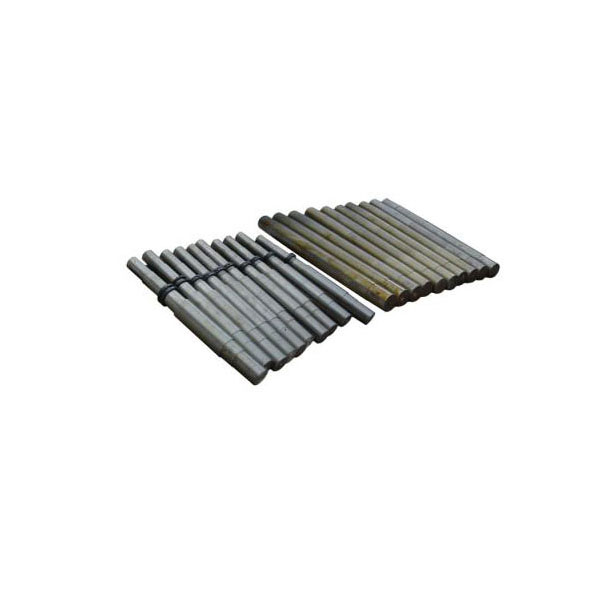

Jaw Crusher Toggle Plate

The toggle plate is a simple and inexpensive, yet very important, part of the jaw crusher.

It is usually made of wear-resistant material and is used to hold the lower part of the jaw in place, as well as serving as a safety mechanism for the entire jaw.

If something that the jaw crusher cannot crush accidentally enters the crushing chamber and cannot pass through the jaw, the toggle plate will crush it and prevent further damage to the machine.

The toggle plates for the jaw crushers we produce are made with the addition of rare and precious metals such as chromium, vanadium, boron, molybdenum, etc., and we use special transformation techniques based on the original Mn13 material. This type of product exhibits excellent wear resistance. Based on the mechanical performance of the jaw crusher model at the customer's site, the appropriate heat treatment method for the high-manganese steel is determined to ensure that this type of product achieves its maximum crushing strength and that the toggle plate reaches its brittle fracture point.

Why choose toggle plates from Zhili New Materials?

① We offer equivalent OEM replaceable toggle plates;

② We produce high-strength toggle plates to better transmit crushing force to the rear of the body structure;

③ We extend the service life of the toggle plates;

④ We offer more competitive prices;

⑤ We offer more professional services and suggestions.

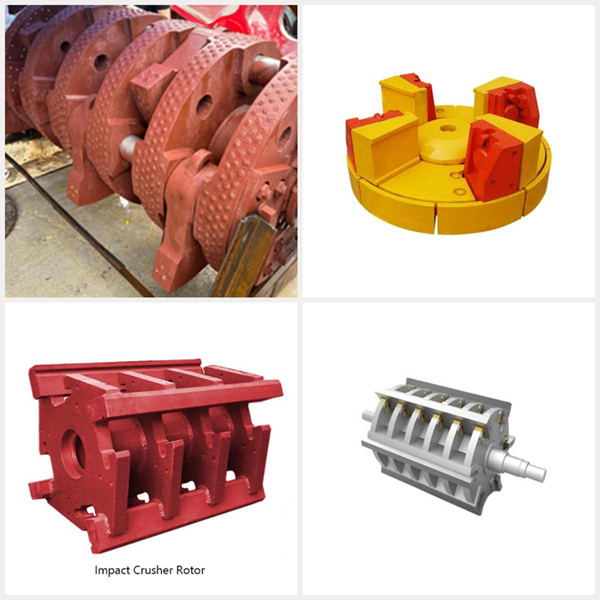

Related Products