Vertical mill/ Roller press Coating roller

Global sales Custom OEM Design

Product Name: Vertical Mill/Roller Press Coating Roller/Roller Press Hard Coating Roller

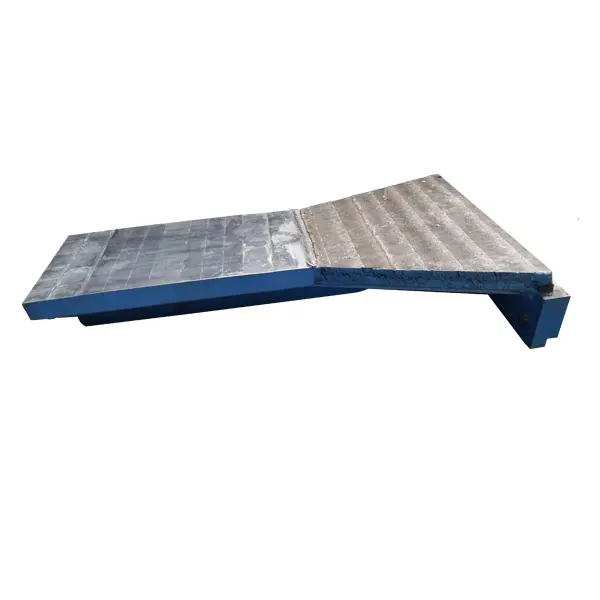

Production Process: Forging and Coating

Applicable machines: Roller press, Vertical mill

Material types: 35CrMoA or 42CrMoA + hard coating layer

Applicable Industries: Cement, chemicals, electricity, metallurgy, building materials, refractory materials

Suitable Materials: Cement, limestone, slag, coke, coal and other materials

Our Service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a factory specializing in spare parts for roller presses.

The material of the extrusion roll of the roller press is 42CrMo and 35CrMo, and can be manufactured according to the customer's specific needs.

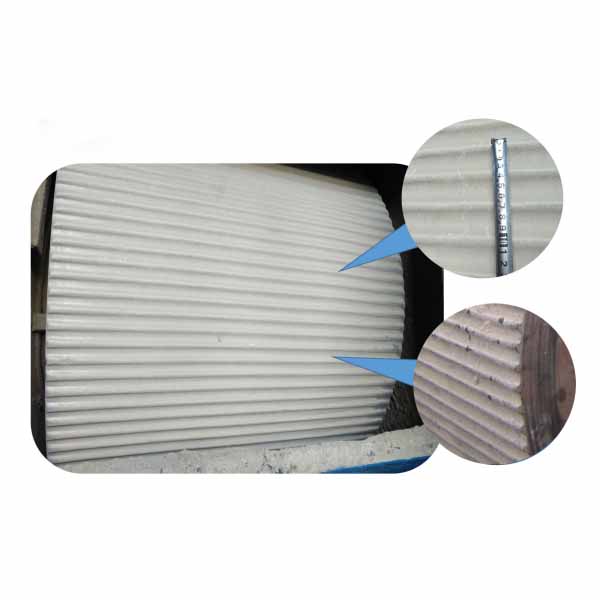

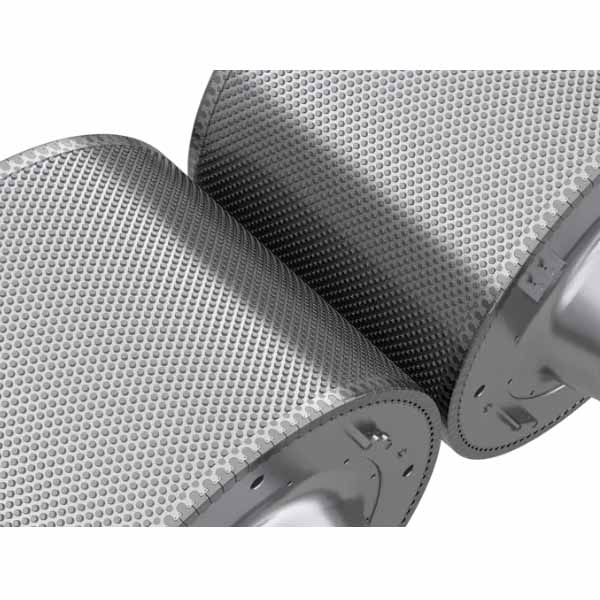

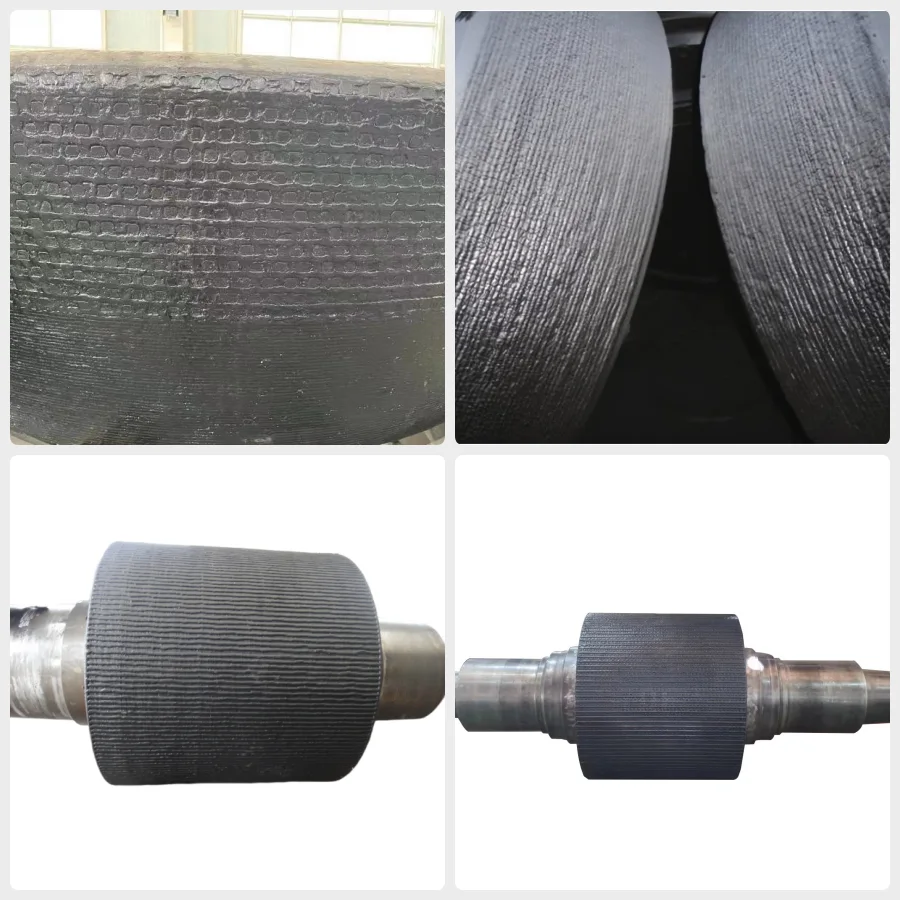

The base of the coating roll is made of low-alloy forged steel, with high strength and good toughness. Then, the surface of the base is coated, and the circumferential insulating coating is applied circle by circle and layer by layer. The surface patterns of the coating roll include single-line pattern, diamond pattern, circumferential wave pattern, herringbone pattern, etc. The roll sleeve has high surface hardness, wear resistance, suitable inner bore hardness, convenient processing and embossing, low cost, low price, and long service life.

Introduction to the extrusion roll coating process:

1. Remove the residual hard layer and cracks on the roller surface. Use air gouging with a carbon arc to thoroughly clean the roller surface area, removing the residual hard layer, cracks, dust, rust, etc., and polishing to reveal the metallic shine.

2. Welding the base layer. Use ZD1 welding wire for welding. By welding the bottom layer, the uneven surface of the roller forms a relatively flat outer cylindrical surface, which is convenient for welding the protective layer and the wear-resistant layer.

3. Use ZD2 welding wire to weld the protective layer. ZD2 welding wire is a high-strength, medium-hardness surface material with good fatigue resistance and good adhesion, while also possessing some wear resistance, playing a good bridging role between the roll body and the wear-resistant layer. Proper selection of the damping layer material and welding are important prerequisites to ensure the safe and effective operation of the wear-resistant layer.

4. Use ZD3 welding wire to weld the wear-resistant layer. Pay attention to measuring the size and circularity of the roll body during welding and weld until the roll body reaches the required size.

5. Finally, weld the horizontal wear-resistant bars. After welding the wear-resistant layer, use ZD310 welding wire to weld the horizontal bars.

It is suitable for medium and fine crushing of medium-hardness materials such as limestone, slag, coke, coal, and other materials in the cement, chemical, electric power, metallurgy, building materials, refractory materials, and other industrial sectors.

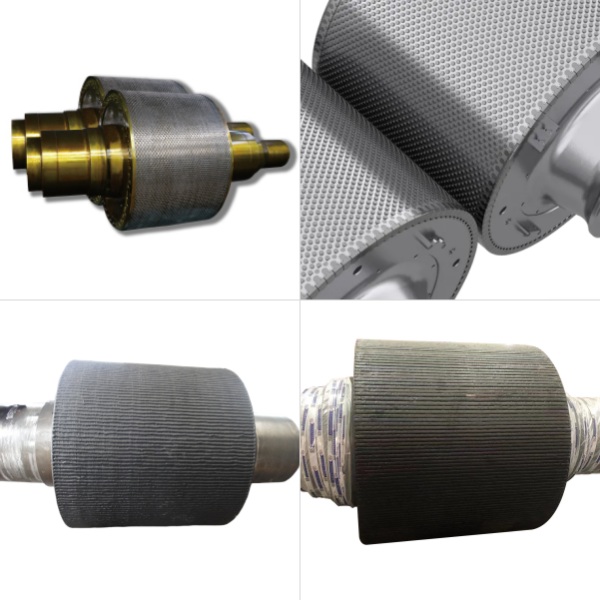

The roller sleeve can be replaced and the surface repaired according to customer usage, so that customers can reuse discarded rollers with the most economical and effective products and services. At the same time, new rollers can be manufactured according to customer drawing requirements, providing solid support to meet their production needs.

Introduction to the production process of rollers and roller sleeves:1. The new roller or roller sleeve is made of 35CrMo or 42CrMo forged steel, and the thickness of the roller sleeve is not less than 220 mm or equal to the thickness of the original roller sleeve.

2. The forged part is hardened and tempered, and flaws are detected.

3. Machining of rollers and roller sleeves according to the size requirements of the composite drawing.

4. A thickness of 20㎜ is reserved on the surface of the new roller and roller sleeve for coating.

Related Products