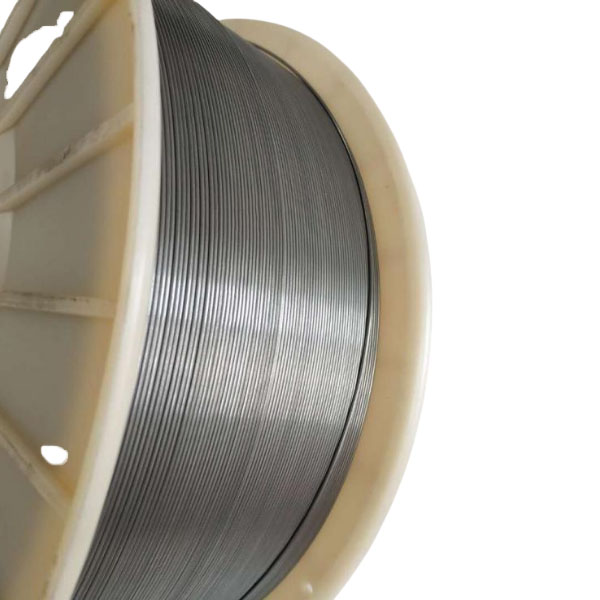

Hard coating of wires and tubular electrodes

Global Sales Custom OEM Design

Product Name: Flux-Cored Welding Wire/Welding Wire/Metallized Wire/Hardfacing Flux-Cored Wire/Welding Bar

Applicable Machines: Roller Press, Vertical Mill Grinding Roller, High Pressure Grinding Roller (HPGR), Crusher Jaw Plate, Impact Bars, Bucket Teeth, Crusher Hammers, Pump Impellers and Liners, etc.

Types of materials: High-chromium cast iron, alloy steels, nickel-based alloys, cobalt-based alloys, etc.

Applicable Industries: Cement, chemical, electricity, metallurgy, building materials, etc.

Suitability for base material: Q235, 42CrMo, low carbon steel, high manganese steel, nickel-based alloys, etc.

Our Services:

1. Before the sale, we will fully understand the client's working conditions and recommend the most suitable material selection.

2. Provide clients with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

4. Ensure that the quality of the purchased components is impeccable and that the technical parameters fully meet national standards.

5. Provide free quotations, worldwide sales, short delivery times, and low prices.

If you need detailed technical information about the product or cannot find the desired product on the website, please send us an email (cnwearparts@lyzhili.com), as we are a custom manufacturer of wear replacement parts.

We are a professional manufacturer of tubular welding wires and electrodes for cladding, as well as wear-resistant plates. We have several wire production lines and produce welding materials in various series and specifications. You can make a reasonable choice according to your base material and working conditions.

The main series of tubular wire electrodes for cladding and their conditions of use are as follows:

1. The ZD series is a high-carbon, high-chromium cast iron coating material reinforced by multiple alloys. It is suitable for manufacturing pre-protective coatings and for repairing coatings after wear of parts under severe abrasion and light impact mining conditions. It is mainly used for wear-resistant coatings on vertical mill rolls, grinding discs, and other wear-resistant plates.

2. The ZM series is suitable for coating metals with excellent crack resistance and impact toughness. It is used for coating comprehensive transition layers in roller press repairs and exhibits excellent crack resistance.

3. The GM series is especially used for base coating during the repair of high manganese and ultra-high manganese steel parts.

4. The TD and TM series are mainly used for repairing severely worn parts of crusher hammers.

5. The MD501 is used for repairing old crusher hammer parts and hammer discs on-site. The coating layer shows cracks, but the wear resistance is excellent and does not affect use.

6. The DH series is mainly used for pre-protection coating in the manufacture of new fans and is also commonly used for repairing various types of worn parts at ambient temperature.

7. The TA series is mainly used for repairing parts subject to severe abrasive wear and moderate impact at high temperatures, such as fan blades, concrete pump parts, etc. Its anti-wear performance is superior to that of tungsten carbide welding rods.

Related Products