Crusher hammer heads

Global Sales OEM Custom Design

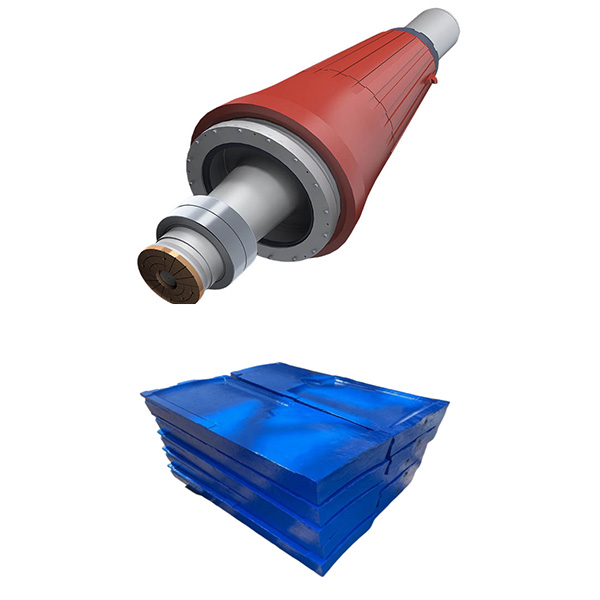

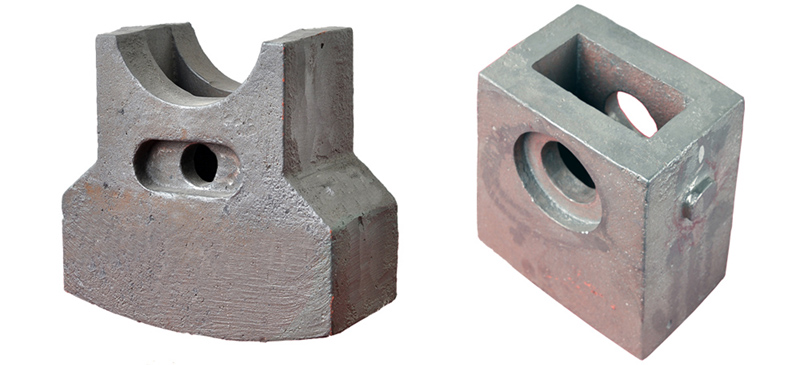

Product Name: Hammer Crushers

Production Process: Casting

Applicable Machines: Clinker crusher, raw material crusher, auxiliary material crusher, metal crusher, etc.

Applicable Industries: Cement, stone, coal, steel, metal recycling, etc.

Suitable Materials: Granite, basalt, limestone, river pebbles, cement clinker, quartz, iron ore, bauxite, salt, brick, coal, etc.

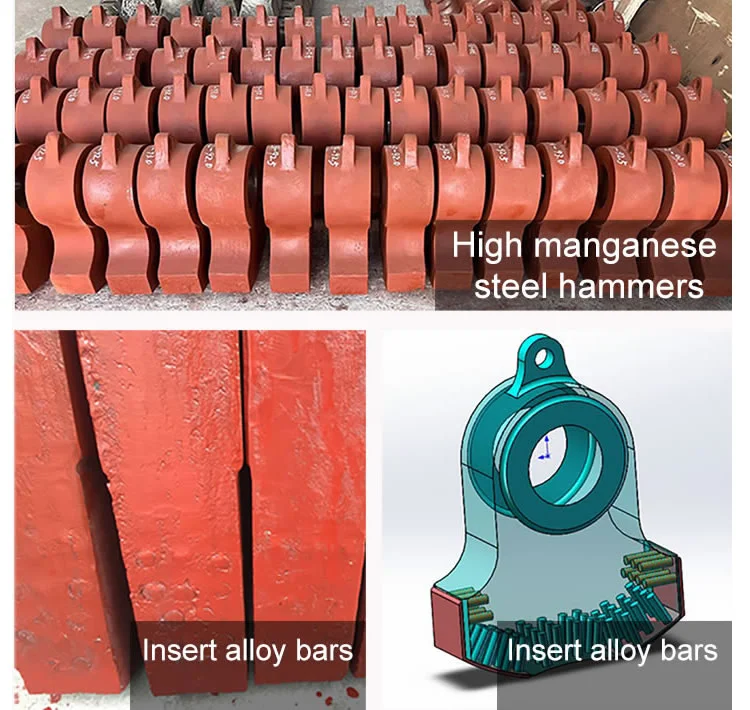

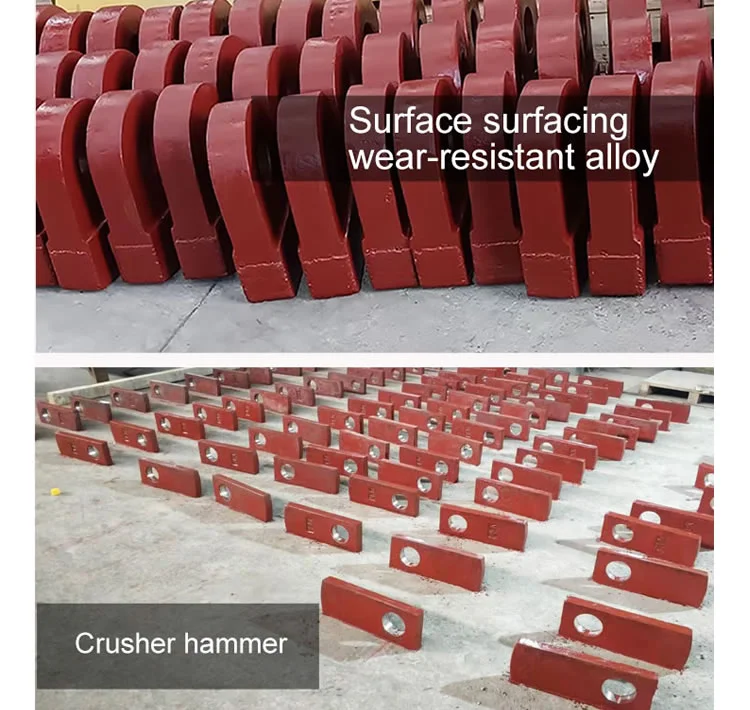

Types of materials: High manganese steel, high manganese steel insert alloy bars, high manganese steel + hardfacing, bimetallic composite, high chromium cast iron, alloy steel, etc.

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

4. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information about the product or cannot find the desired product on the website, please send us an email (info@lyzhili.com), as we are a custom factory for crusher spare parts.

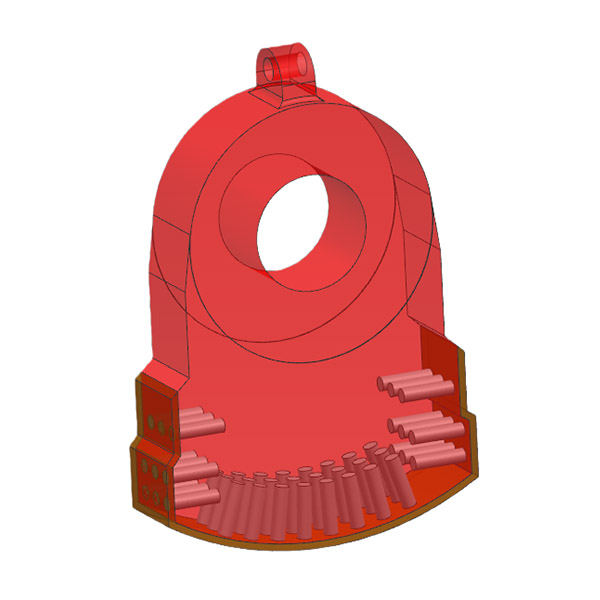

The materials for high-manganese steel hammer heads include tungsten-molybdenum alloy bars with Mn13Cr2, Mn18Cr2, Mn13, or Mn18 inserts and wear-resistant surface coating alloys.

When the high-manganese material withstands high impact force from the stone, its surface hardens rapidly and forms a wear-resistant surface layer. The hard alloy bar with insert showed good anti-friction, hardness, and wear resistance performance. Toughness

Features:Good toughness, good manufacturability, low price, but the overall performance requirements of the crusher are higher.

Applicable working conditions: Suitable for cement plants, metal recycling, stone factories and other rocky locations with poor conditions.

Chemical component

Grade | Chemical component% | |||||

|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | S | P | |

| ZG120Mn13 | 1.05~1.35 | 0.3~0.9 | 11~14 | - | ≤0.06 | ≤0.04 |

| ZG120Mn13Cr2 | 1.05~1.35 | 0.3~0.9 | 11~14 | 1.5~2.5 | ≤0.06 | ≤0.04 |

| ZG120Mn17Cr2 | 1.05~1.35 | 0.3~0.9 | 16~19 | 1.5~2.5 | ≤0.06 | ≤0.04 |

1: Permite adicionar microescalas V, To, B e Re, etc. 2: Podemos produzir martelos de aço de alto manganês de outros graus, de acordo com as necessidades do cliente. | ||||||

Propriedade Mecânica

Grade | Propriedade de estiramento | Hardness HB | |||

|---|---|---|---|---|---|

| yield strength ReH/Mpa | tensile strength Rm/Mpa | Elongation at cross section % | Shock absorption energyKu2J | ||

| ZG120Mn13 | - | ≥685 | ≥25 | ≥118 | ≤300 |

| ZG120Mn13Cr2 | ≥390 | ≥735 | ≥20 | - | ≤300 |

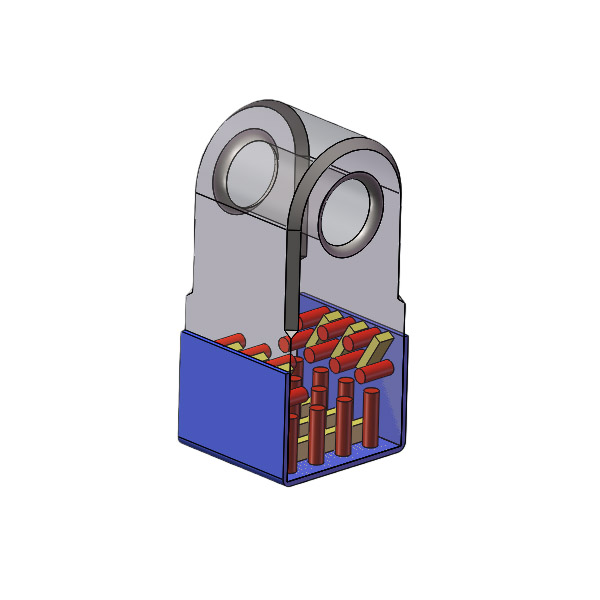

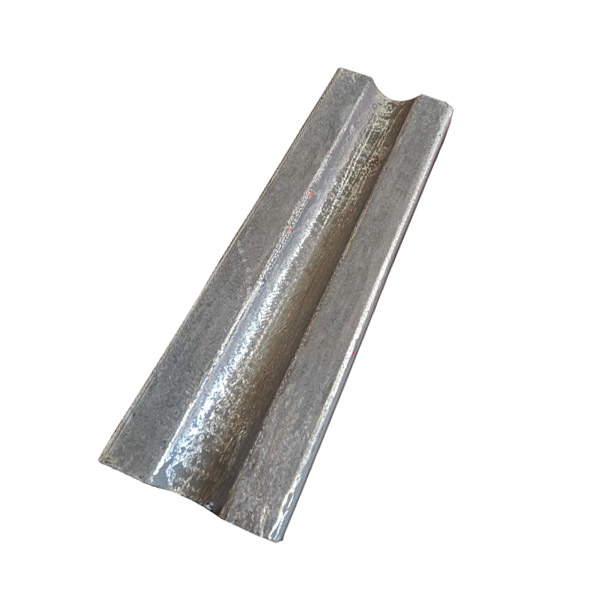

The working part of the hammer head is made of high-chromium cast iron, with high wear resistance, and the handle is made of high-tenacity alloy steel.

Features:High wear resistance

Applicable working conditions:Limestone, cement clinker, iron ore, sandstone, coal gangue, basalt and other hard stone crushing areas.

Operating principle:The motor drives the rotor to rotate at high speed in the crushing chamber. The hammer is the main wear part, and the quality of the hammer directly affects the crushing efficiency of the crusher. During operation, the hammer is not only hit but also impacted by the material. If used repeatedly for a long period, the working surface of the hammer will be damaged and the shape of the surface will change.

We use appropriate alloys and related technological measures to ensure that the surface hardness of the high-chromium iron hammers reaches more than 58 HRC and, during the wear process, maintains high hardness and high wear resistance.

Applicable working conditions:Suitable for the manufacture of wearable replacement parts with lower impact load and simpler shape.

Componente químico

| Grade | Chemical component% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| BTMCr15 | 2.0~3.3 | ≤1.2 | ≤2.0 | 14~18 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr20 | 2.0~3.3 | ≤1.2 | ≤2.0 | 18~23 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23~30 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.10 |

1: Allows adding microscale values for V, Ti, Nb, B, Re, etc. 2: We will select the specific class and component according to the weight, thickness, and size of the impact bars. | |||||||||

Propriedade Mecânica

Grade | Surface Hardness | |||||

|---|---|---|---|---|---|---|

Casting condition | Harded condition | Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| BTMCr15 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr20 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr26 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

Related Products