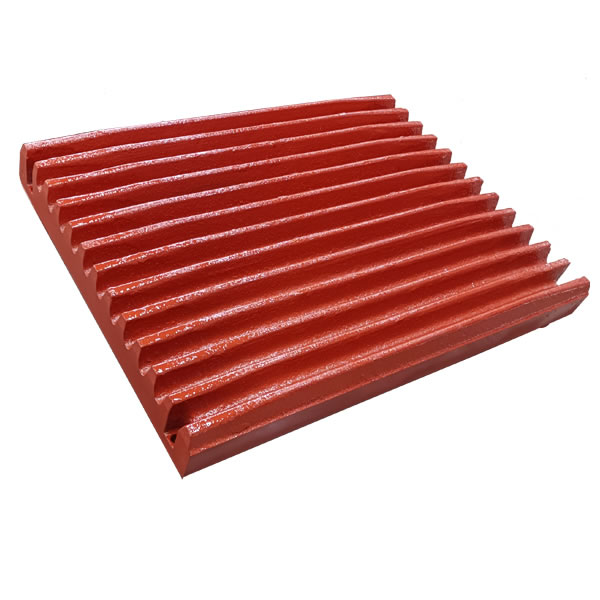

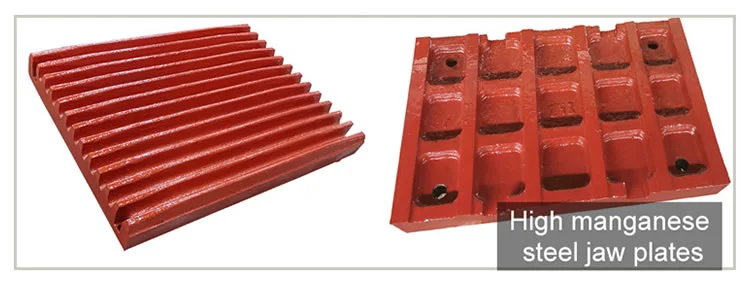

Jaw plates

Global sales Custom OEM Design

Product Name: Jaw Plate/Rotating Jaw Plate/Fixed Jaw Plate/Moving Jaw Plate/Jaw Crusher Liners

Production Process: Casting

Applicable Machines: Jaw Crushers

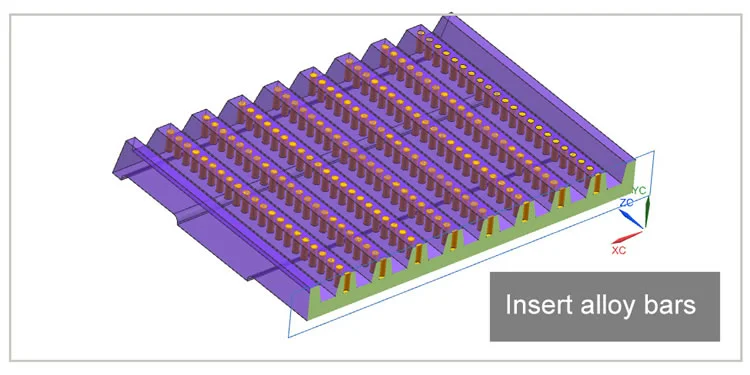

Types of materials: High manganese steel, high manganese steel insert alloy bars, high manganese steel + hard coating layer, high chromium cast iron, alloy steel, etc.

Applicable industries: Mining, cement plants, coal, steel, etc.

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send an email to (info@lyzhili.com), as we are a factory specializing in spare parts for crushers.

Our jaw plates are cast from the highest grade of ferromanganese, providing the hardest composition and maximum wear resistance. We offer a wide variety of tooth profiles and surface shapes to best suit your crushing needs.

The jaw plate is an essential replacement part for wear resistance in the jaw crusher. A jaw plate assembly consists of a movable jaw plate and a fixed jaw plate.

The materials for high-manganese steel jaw plates include tungsten-molybdenum alloy bars Mn13Cr2, Mn18Cr2, Mn13 or Mn18 insert and wear-resistant alloys for surface coating.

Applicable working conditions:Suitable for cement plants, stone factories and other rocky locations with harsh conditions.

Zhili New Materials jaw plates have the following characteristics:

1. Designed for maximum operational flexibility;

2. Maximize uptime;

3. Reduce wear;

4. Optimize production;

5. Extend service life.

Chemical component

Grade | Chemical component % | |||||

|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | S | P | |

| ZG120Mn13 | 1.05~1.35 | 0.3~0.9 | 11~14 | - | ≤0.06 | ≤0.04 |

| ZG120Mn13Cr2 | 1.05~1.35 | 0.3~0.9 | 11~14 | 1.5~2.5 | ≤0.06 | ≤0.04 |

| ZG120Mn17Cr2 | 1.05~1.35 | 0.3~0.9 | 16~19 | 1.5~2.5 | ≤0.06 | ≤0.04 |

1: Permite adicionar microescalas V, To, B e Re, etc. 2: Podemos produzir martelos de aço de alto manganês de outros graus, de acordo com as necessidades do cliente. | ||||||

Mechanical Property

Notice | Mechanical Property | Dureza HB | |||

|---|---|---|---|---|---|

| limite de escoamento ReH/Mpa | resistência à tracção Rm/Mpa | Alongamento na seção transversal % | Energia de absorção de choque Ku2J | ||

| ZG120Mn13 | - | ≥685 | ≥25 | ≥118 | ≤300 |

| ZG120Mn13Cr2 | ≥390 | ≥735 | ≥20 | - | ≤300 |

We use appropriate alloys and related technological measures to ensure that the surface hardness of the high-chromium iron jaw plates reaches more than 58 HRC, maintaining high hardness and high wear resistance during the wear process.

Applicable working conditions:Suitable for manufacturing wearable replacement parts with lower impact load and simpler shape.

Chemical component

Grade | Chemical component % | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| BTMCr15 | 2.0~3.3 | ≤1.2 | ≤2.0 | 14~18 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr20 | 2.0~3.3 | ≤1.2 | ≤2.0 | 18~23 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23~30 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.10 |

1: Permite adicionar microescala de V, Ti, Nb, B, Re, etc. 2: Selecionaremos a classe e o componente específico de acordo com o peso, espessura e tamanho das barras de impacto. | |||||||||

Propriedade Mecânica

Grade | Dureza da superfície | |||||

|---|---|---|---|---|---|---|

Casting condition | Hardened condition | Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| BTMCr15 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr20 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr26 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

1: Não há uma correspondência exata entre a dureza Rockwell (HRC) e a dureza da salmoura (HB), portanto, esses dois tipos de valores de dureza podem ser utilizados. 2: A dureza na seção de fundição com profundidade de 40% deve ser inferior a 92% da dureza da superfície. | ||||||

The alloy steel jaw plate is widely used today. It has relatively high hardness and adequate toughness, sufficient to resist fluid wear and repeated material impact, exhibiting good wear resistance performance.

Applicable working conditions: Widely used in cement plants, quarries and mining.

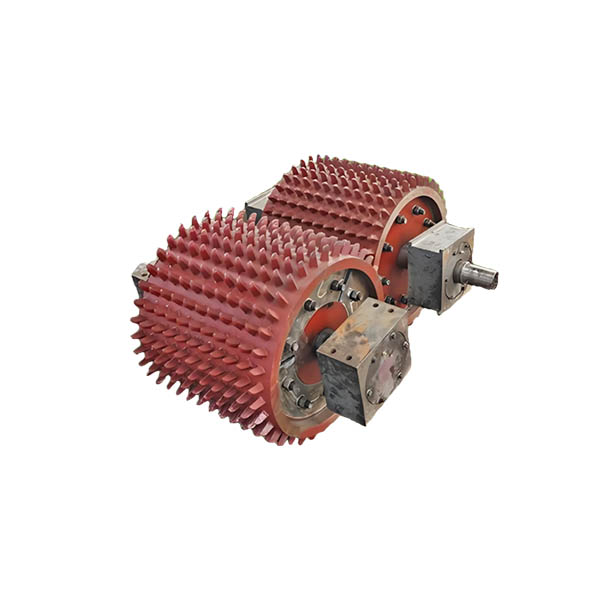

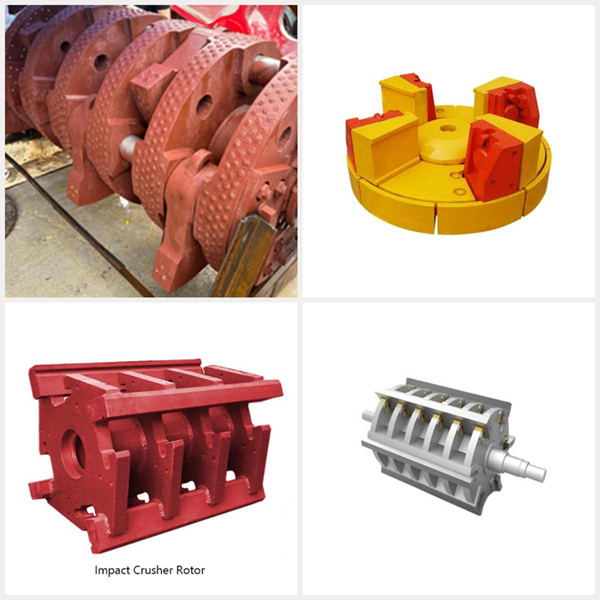

Related Products