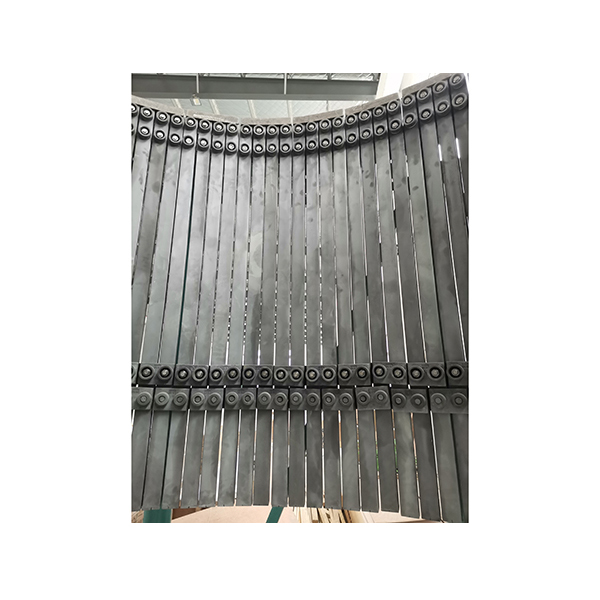

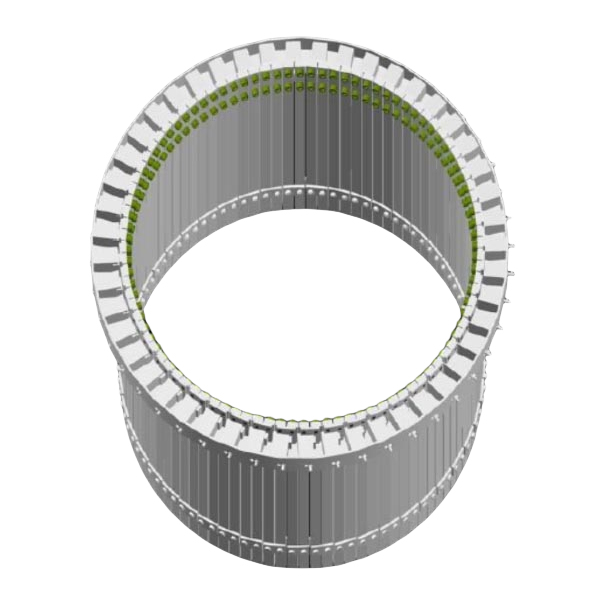

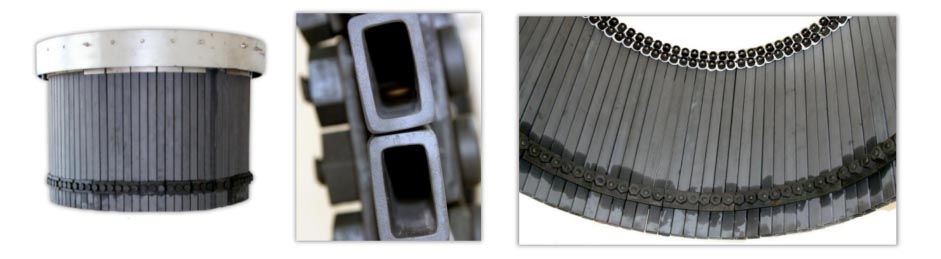

Inner cylinder of the preheater

Global Sales - OEM Custom Design

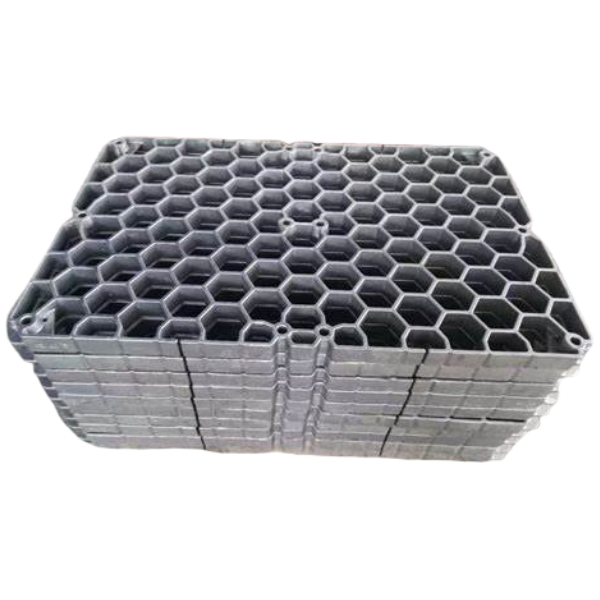

Product Name: Preheater Inner Cylinder/Ceramic Inner Cylinder/Heat-Resistant Steel Inner Cylinder

Production Process: Casting, Forging

Material Types: Al₂O₃ Ceramic, SiC Ceramic, Ceramic-Metal Composite, Carbon Steel, Heat-Resistant Steel Heat, high-chromium cast iron, alloy steel, etc.

Applicable industries: Cement, metallurgy, chemical industry, steel industry, petroleum, electricity, new energies, etc.

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical product information or cannot find the desired product on the website, please email us (info@lyzhili.com), as we are a custom factory of heat-resistant steel castings.

In cement preheaters, ceramic inner tubes have become the preferred solution for key components (such as cyclones, heat exchange tubes, decomposition furnaces, etc.) due to their excellent resistance to wear, high temperature, and chemical corrosion.

When selecting, it is necessary to carefully consider the operating temperature, corrosiveness, and budget. Silicon carbide ceramics should be used primarily in high-temperature and high-wear areas (such as C4-C5 and decomposition furnaces), while high-aluminum ceramics can be used in medium and low-temperature sections. Silicon carbide ceramics offer the best overall performance but at a high cost, while high-aluminum ceramics offer better cost-effectiveness.

In cement preheaters, the heat-resistant steel inner cylinder is an important component between common metals and ceramics. It is suitable for medium and high temperature sections (such as C3-C5 grade cyclones or heat exchange tubes) and must meet the requirements of high temperature resistance, oxidation resistance, and a certain degree of wear resistance.

The heat-resistant steel inner cylinder still offers irreplaceable advantages under working conditions of 800-1100°C, being particularly suitable for production lines with frequent starts and stops or high mechanical vibration. When the temperature exceeds 1150°C, a transition to a ceramic and metal composite structure is recommended.

Related Products