Heater-powered scraper

Global sales OEM Custom Design

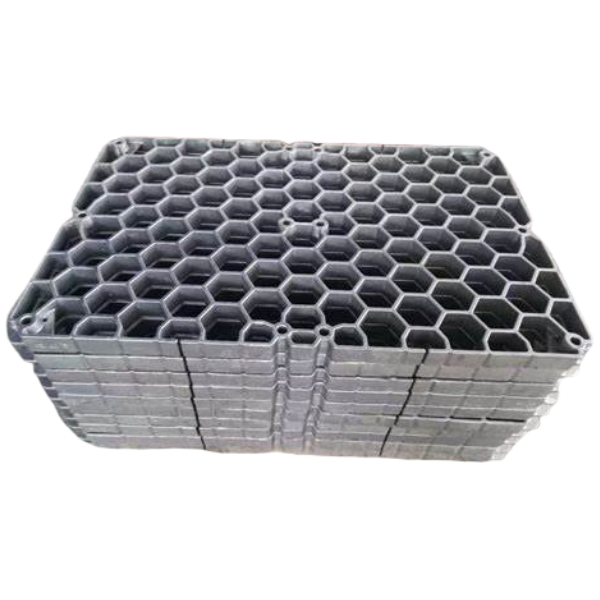

Product Name: Heat-Resistant Steel Slice/Scraper for Preheater/Heat-Resistant Steel Slice for Oven Preheater

Production Process: Precision Casting, Sand Casting, Lost Foam Casting, Centrifugal Casting

Types of Materials: 1Cr10MoW2VNbN, 12Cr1MoV, 25Cr2MoVA, 12Cr2MoWVTiB, etc.

Applicable Industries: Cement, metallurgy, chemical industry, steel industry, pellets, etc.

Our service:

1. Before the sale, we will fully understand the customer's working conditions and recommend the most suitable material selection.

2. We will provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After the sale, we will continue to monitor the product's use and provide timely assistance.

If you need detailed technical information about the product or cannot find the desired product on the website, please send us an email (info@lyzhili.com), because we are a factory that customizes heat-resistant steel castings.

Classification of heat-resistant steel by normalized structure: austenitic heat-resistant steel, martensitic heat-resistant steel, ferritic heat-resistant steel, and pearlite heat-resistant steel, etc.

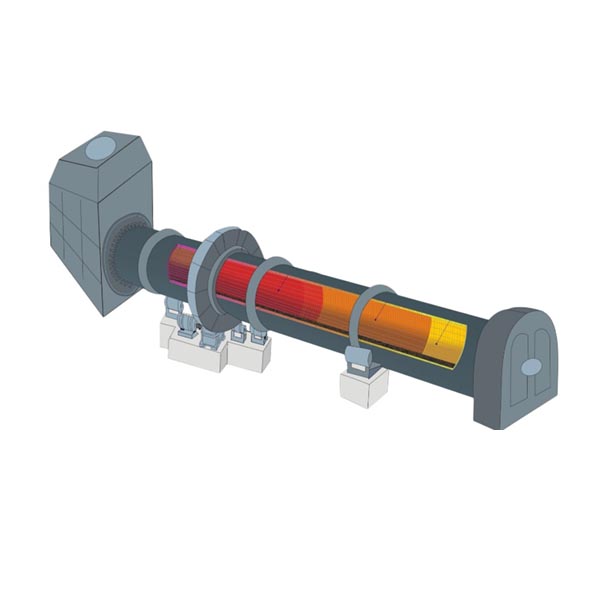

Application: Installed in the inner cylinder of the preheater cyclone. The product can utilize different types of heat-resistant steel, according to the usage requirements, environment, and conditions of different industries.

Characteristics: high temperature resistance, corrosion resistance, wear resistance, high sulfur resistance, impact resistance, easy cutting, weldable, etc.

1. It has high strength and good chemical stability at high temperatures, as well as overall safety, drop resistance, and good stability;

2. It has good corrosion resistance at high temperatures and a long service life, being 1.5 to 2 times longer than other hanging materials;

3. It can be used continuously in high-temperature environments, has good resistance to thermal fatigue and high resistance to high temperatures, is not easily prone to thermal cracking after repeated use, and can be used at high temperatures above 1400°C.

Related Products