1. Performance characteristics of the ceramic-metal composite vertical mill roll; 2. Performance characteristics and structural diagram of the grinding table/ceramic-metal composite vertical mill roll lining....

Luoyang Zhili New Materials, founded in 1992, is one of the world's leading processing centers for wear-resistant materials, providing high-quality wear parts services to the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

1. Performance characteristics of ceramic-metal composite table/vertical roller liners developed by our company

Safe and reliable structure

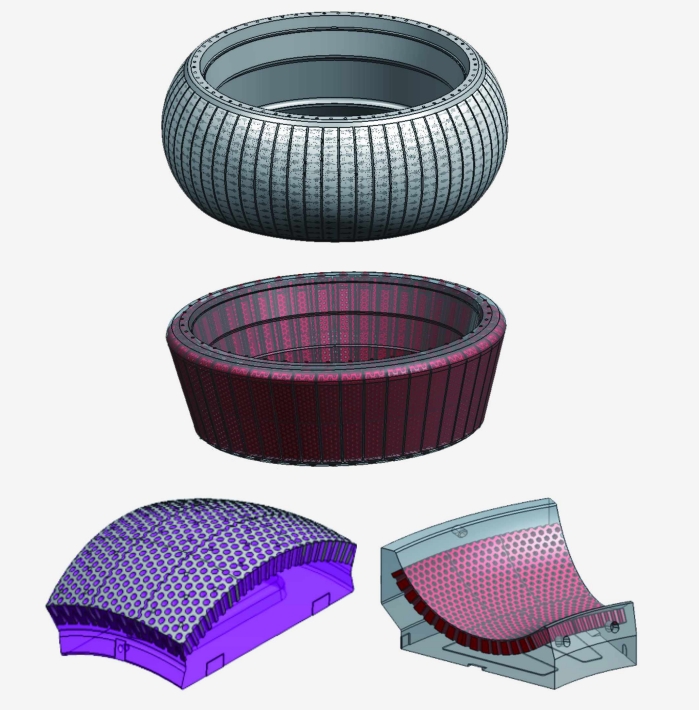

The ceramic-metal composite roller sleeve is composed of a wear-resistant strip of ceramic and high-chromium alloy and a high-tenacity ductile iron base material. The unique structure possesses wear resistance and stability characteristics.

Improved wear resistance

The wear-resistant strip is composed of high-hardness ceramic, which increases wear resistance by 2 to 3 times, and the wear is uniform, which can maintain the original appearance of the wear parts for a long time, and the stability of the operation is greater.

High Grinding Efficiency

After the wear of the wear-resistant parts, a ceramic metal honeycomb structure is formed on the surface, which increases the grinding area of the surface and material, as well as the bite force, and improves grinding efficiency.

Custom Solution Design

According to the customer's wear conditions, the wear-prone area is increased and the wear line is more uniform.

High economic benefits

Long service life, high stability, reduced production losses caused by downtime, replacement or repair, reduced maintenance costs and more robust maintenance planning.

Material savings and environmental protection

It prevents harmful gases generated during the coating process of alloy roller liners, reducing steel use and carbon dioxide emissions.

2. Performance characteristics and structural diagram of the ceramic and metal composite vertical mill/grinding table lining

3. Application cases of ceramic and metal composite vertical mill/grinding table lining

RM51/26 raw material vertical mill for a cement company

|

Material |

Date of commissioning |

Date of inspection |

Elapsed time (h) |

Maximum wear depth(mm) |

Average wear depth(mm) |

Output per hour(t/h) |

|

High chromium cast iron |

Late January 2018 |

Early May 2018 |

1840 |

32 |

17 |

380 |

|

Hardfacing composite |

Late January 2018 |

Early May 2018 |

1840 |

32 |

18 |

380 |

|

Ceramic metal composite |

Late May 2020 |

Early May 2021 |

8110 |

36 |

28 |

397 |

Rolo de esmerilhamento em ferro fundido com alto teor de cromoRevestimento duroRolo de esmerilhamento Composto de metal cerâmico rolo de moagem

Related articles

1. Performance characteristics of the ceramic-metal composite vertical mill roll; 2. Performance characteristics and structur...

They learned mainly about the jaw plate, side guard plate, toggle plate, eccentric shaft, and other accessories related to th...

We offer 24-hour service. Heat-resistant steel products are also high-strength products from our company, mainly suspended pl...

Today, a customer from Asia came to visit the factory. Our colleagues drove him there. They found our workshop environment re...

Our technology has developed a new stu+ coating roller, whose base is made of high-strength alloy steel and studs. The presen...

In 2023, a cement factory in Qatar ordered a set of limestone crusher hammers from our factory. The material is high-manganes...