In practical applications, the ideal selection of the divider plate material must be tailored to the specific operating conditions and production requirements to maximize grinding efficiency and the economic benefits of the rod mill....

Luoyang Zhili New Materials, established in 1992, is one of the leading processing centers for wear-resistant materials in the world, providing high-quality service for wear parts in the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

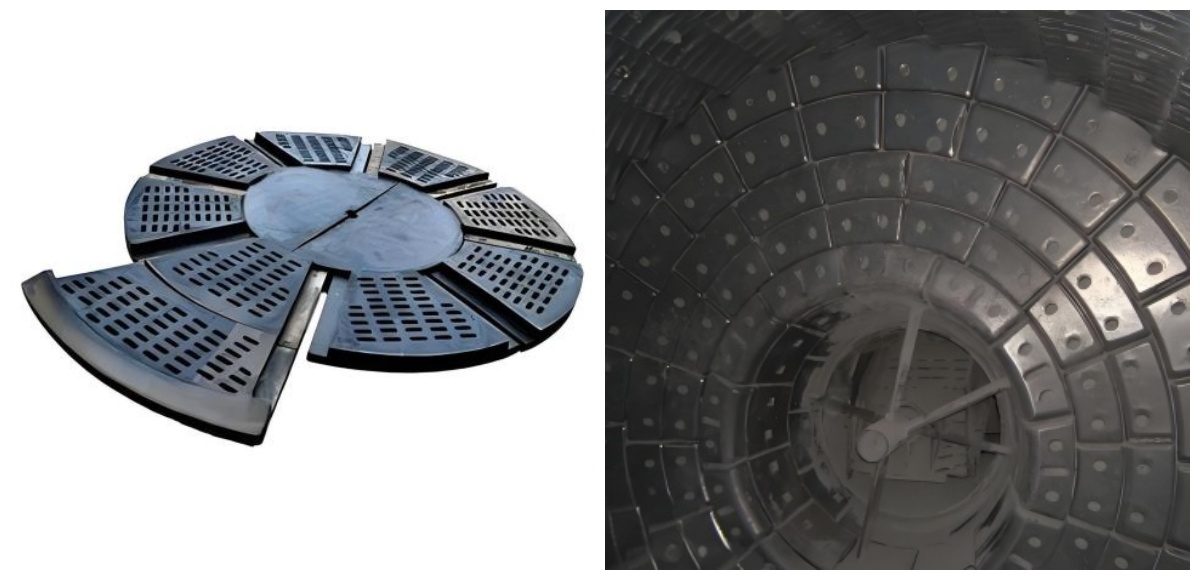

Rod mills are a type of grinding equipment widely used in industries such as mining and cement. The baffle plate is an essential component of the rod mill. The material properties of the baffle plate directly impact the grinding efficiency, lifespan, and operating costs of the mill, making the choice of the correct material for the baffle plate crucial.

The baffle plate divides the interior of the mill into different chambers, allowing the grinding medium to move in different states and perform different grinding functions within each chamber. It also controls the flow rate and direction of the material within the mill. Baffle plate wear mainly involves impact wear and abrasive wear. Impact wear is caused by the impact of steel bars, resulting in plastic deformation, cracking, and even scaling on the surface of the deflector plate. Abrasive wear is caused by the relative movement of the material against the surface of the deflector plate, cutting and grinding the plate surface. In addition, impurities and hard objects in the material can aggravate the wear of the deflector plate. Choosing the correct material for the deflector plate can effectively reduce plate wear and extend its service life.

Common Materials for Baffle Plates in Rod Mills and Their Performance Characteristics

(I) High Manganese Steel

High manganese steel has excellent toughness and work hardening properties. When subjected to impact loads, its surface hardens rapidly, increasing its hardness and wear resistance. However, in a rod mill, if the impact force of the grinding medium on the baffle plate is insufficient, the high manganese steel will not work harden completely and its wear resistance will be affected. In addition, high manganese steel has a low yield strength, is prone to plastic flow and bulging deformation. It is also non-magnetic, which makes it unsuitable for applications requiring iron absorption.

(II) High Chromium Cast Iron

High chromium cast iron offers high hardness and wear resistance, reaching hardnesses of 55-62 HRC, and a long service life. However, high chromium cast iron has low toughness, with an impact toughness generally ranging from 4 to 10 J/cm². When used as a material for baffle plates in rod mills, it is prone to fractures under high impact loads. In addition, high chromium cast iron contains a large amount of precious metals, which makes it relatively expensive.

(III) Medium Carbon Multi-Element Alloy Steel

Medium carbon multi-element alloy steel is a relatively ideal material for baffle plates. Its hardness can reach approximately HRC55, its tensile strength σb > 900 N/mm², and its wear resistance is close to or equivalent to that of high-chromium cast iron and approximately three times greater than that of high-manganese steel. In addition, medium-carbon multi-element alloy steel offers excellent toughness, with an impact toughness of 20 to 30 J/cm², significantly higher than that of high-chromium cast iron. This material is simple to manufacture, has abundant raw material resources, and is relatively inexpensive.

The selection of the divider plate material for a rod mill must consider several factors, including operating conditions, cost, and service life. In practical applications, the ideal selection of divider plate material should be adapted to the specific operating conditions and production requirements to maximize grinding efficiency and the economic benefits of the rod mill.

Related articles

During the operation of the OK mill (vertical mill), due to direct contact with materials, high pressure, high temperature, a...

We supply spare parts for hammer crushers, jaw crushers, cone crushers, impact crushers, and vertical mills. As an industry-l...

Our company independently develops a series of hard alloy surface products that can effectively extend the service life of we...

Zhili New Materials Company primarily manufactures crusher accessories, such as hammer heads, impact bars, rotors, liners, an...

The best and brightest in the cement industry are gathering in Birmingham, Alabama, from May 4-8, at the Birmingham Jefferson...

Hammer crushers, impact bars, linings, etc., are products that our company has been manufacturing for a long time, and their ...