Made from integral ZG35CrMo steel, this rotor eliminates welding risks and has an impact resistance of 35 J/cm². It can withstand direct impacts from hard rocks measuring 500 mm x 500 mm, and its failure rate during continuous operation is 62% lower than that of welded rotors....

Luoyang Zhili New Materials, established in 1992, is one of the leading processing centers for wear-resistant materials in the world, providing high-quality service for wear parts in the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

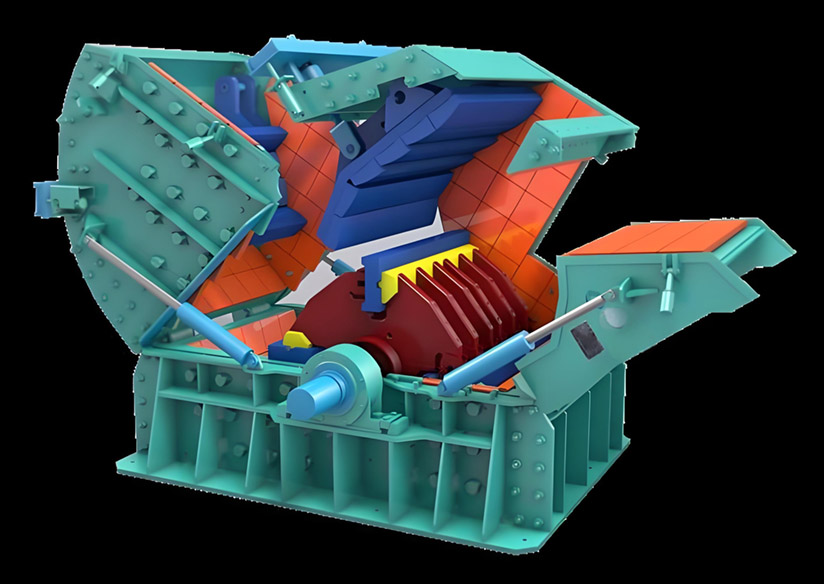

In the operation of an impact crusher, the rotor fulfills three main responsibilities: energy transfer, material crushing, and stable operation. The rotor's high rotational speed (750-1500 rpm) drives the hammers to generate a powerful impact force, instantly crushing hard rocks such as granite and basalt. It also provides rebound kinetic energy for secondary crushing, directly determining more than 30% of the equipment's processing efficiency and 25% of its service life.

Whether processing sand and gravel for hydroelectric projects or recycling construction waste, choosing the right rotor can increase production line capacity by 45% and reduce downtime by 62%, making it key to reducing cost per ton.

Three conventional rotors precisely adapted to your operational needs.

1. Integral Cast Steel Rotor: The "King of Durability" for Heavy Crushing

Key Advantages: Made of integral ZG35CrMo steel, this rotor eliminates welding risks and has an impact resistance of 35 J/cm². It can withstand direct impacts from hard rocks of 500 mm x 500 mm, and its failure rate during continuous operation is 62% lower than that of welded rotors. Applications: Medium to large-scale production lines with a processing capacity of 100 t/h or more (such as granite and basalt crushing). A hydroelectric power plant project had its annual maintenance costs reduced by 40% and its service life extended to over 8,000 hours. 2. Welded Rotor: The "Economical Choice" for Light Operations Main Advantages: Welded from Q345B steel plates, this rotor is 20% to 30% lighter than a cast steel rotor of the same specification, with a manufacturing cost of only 40% to 60% of that of an integral rotor. It is easy to install and suitable for quick commissioning of small and medium-sized production lines. Suitable for crushing soft rocks (such as limestone and construction waste) with a productivity of less than 50 t/h. A building materials factory uses this rotor to process concrete blocks, keeping the cost per ton below 8 yuan and reducing the return on investment to 6 months.

3. Modular Rotor: A Flexible Tool for Customized Needs

Key Advantages: The modular design reduces the cost of replacing individual modules by 50%. It can be adapted to various impact bars, including long and T-shaped ones, to meet the complex needs of alternating crushing of limestone and concrete.

Suitable for customized production lines for mixed crushing of various materials. After using this product in a recycling company, downtime during material changeover was reduced from 4 hours to 1 hour, increasing annual production capacity by 27%.

The rotor is the "heart of the engine" of the impact crusher, and its performance directly affects the equipment's lifespan. Zhili New Materials Company has extensive experience in the design and manufacture of crusher rotors. Manufacturers with questions can contact us directly, and we will provide a complete and high-quality service.

Related articles

We supply spare parts for hammer crushers, jaw crushers, cone crushers, impact crushers, and vertical mills. As an industry-l...

In practical applications, the ideal selection of the divider plate material must be tailored to the specific operating condi...

O rolo de retificação vertical para soldagem de superfícies incrustadas com pinos de liga é projetado de acordo com as condiç...

The high-manganese steel crushing hammer has good toughness, good manufacturability, and high safety performance. Its main ch...

Our products have also been developed over many years, and various aspects of the technology have been continuously improved....

We will strive to achieve greater advancements as quickly as possible and produce higher quality, more wear-resistant product...