The high-manganese steel crushing hammer has good toughness, good manufacturability, and high safety performance. Its main characteristic is that, under the action of high impact force, the surface will quickly produce a hardened layer....

Luoyang Zhili New Materials, established in 1992, is one of the leading processing centers for wear-resistant materials in the world, providing high-quality service for wear parts in the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

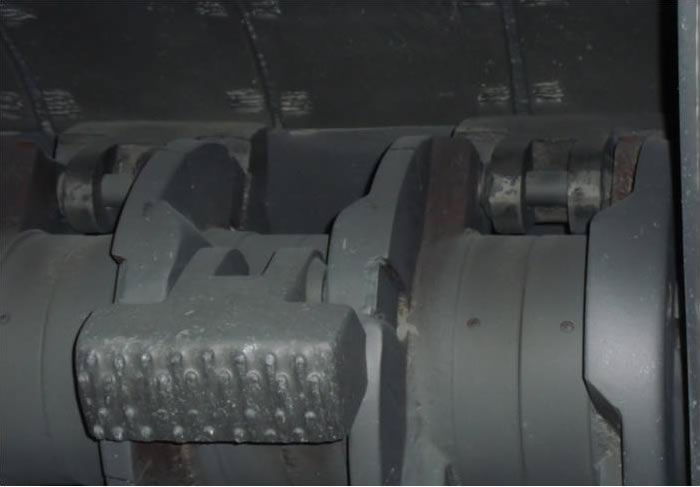

High manganese steel crushing hammer exhibits good toughness, good manufacturability, and high safety performance. Its main characteristic is that, under the action of high impact force, the surface quickly produces a hardened layer. After the hardened surface layer wears away, a new surface emerges. The layer, which continues to be work-hardened, has a work hardening index 5 to 7 times higher than other materials, and high manganese steel undergoes impact work hardening to obtain greater wear resistance. However, the high hardness of high manganese steel is low, wear is severe under medium and low impact forces, and the service life is not long.

According to the defects of high manganese steel, the wear-resistant hammer head with ZG Mn13Cr2 insert is produced by Luoyang Zhili. During casting, we added a tungsten-titanium carbide rod to improve the hardness of the high manganese steel. Tungsten-titanium carbide possesses a number of excellent properties, such as high hardness, wear resistance, tensile strength and toughness, heat and corrosion resistance, with particularly high hardness and wear resistance, which remain virtually unchanged even at a temperature of 500 °C. Hardness remains unchanged and remains high at 1000 °C.

In addition, our wear-resistant hammer head with ZGMn13Cr2 insert, made of tungsten-titanium alloy, adds several rare alloying elements such as molybdenum, vanadium, titanium, nickel, and boron to the tempering rate and strengthens the austenite during the casting process. It is treated with a variety of alloy modifiers, strengthens the matrix, and adds advanced technology to increase grain refinement and enhance the hammer's wear resistance.

The production of the ZGMn13Cr2 insert hammer from our company has been widely praised in the market. The purchasing manager of China Resources Cement Co., Ltd. commented: "We have used hammers from other manufacturers, but the effect was not very satisfactory. However, after using the ZGMn13Cr2 insert hammer produced by Luoyang Zhili, we found that the overall performance is very good, reaching more than 2 times the performance of a common high-manganese steel hammer."

Related articles

In response to customers' desire to improve the production and lifespan of impact bars, our company provides two solutions th...

We will strive to achieve greater advancements as quickly as possible and produce higher quality, more wear-resistant product...

Following ongoing research, it has been discovered that ceramic nanospheres replace traditional steel spheres and have broad ...

Tungsten and titanium alloy steel crushing hammers utilize special technological means, with the hammer head face featuring c...

The Winter Solstice is considered a major winter festival. In ancient China, there was a saying: "The Winter Solstice is...

We supply spare parts for hammer crushers, jaw crushers, cone crushers, impact crushers, and vertical mills. As an industry-l...