Zhili New Materials‘ heat-resistant steel rotary kiln guard plates and chains are preferred by the cement industry. We have a professional team, a product quality guarantee, and impeccable after-sales service....

Luoyang Zhili New Materials, established in 1992, is one of the leading processing centers for wear-resistant materials in the world, providing high-quality service for wear parts in the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

The rotary cement kiln is a special type of rotary kiln for cement processing. The rotary cement kiln currently produced is mainly equipment for paving dry and wet cement clinker production lines. The rotary cement kiln is used to calcine clinker from limestone, clay, etc., to produce cement. Cement production must go through "two grindings and one firing" (i.e., raw material grinding system, clinker calcination system, and cement grinding system). Among them, the clinker calcination system is a thermal process of burning cement raw materials into cement clinker at high temperature, which is an extremely important and critical step in cement production. The material is fed into the kiln through the tail chute of the kiln (upper end). Due to the tilt and slow rotation of the cylinder, the material rolls along the circumference on one side and moves axially from the tail of the furnace (high end) to the head of the furnace (low end); Fuel is sprayed into the furnace from the upper end (lower end) through the burner for combustion, and heat is transferred to the material by radiation and conduction. The material is calcined during movement and discharged from the upper end of the furnace, and the high-temperature combustion gases enter the dust removal system at the lower end of the furnace.

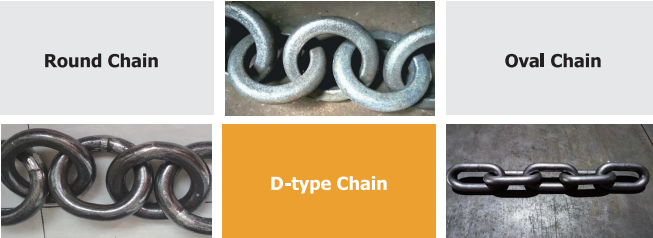

A rotary kiln chain is a heat-resistant accessory for rotary kilns, which primarily increases the heat transfer area, strengthens heat transfer, and accelerates the evaporation of water from the pulp. The temperature of the chain material at the hot end is controlled between 200 and 300°C; some are controlled between 250 and 350°C, and the maximum cannot exceed 400°C. To prevent the chain from burning, the temperature of the combustion gases at the hot end should not be too high. The hot-end chain is made of heat-resistant steel. The rotary kiln mouth guard plate is an important component used to protect the kiln body and the kiln lining. The material commonly used for the kiln mouth guard plate is ZG40Cr25Ni20Si2. This material has excellent high-temperature resistance, oxidation resistance, and corrosion resistance. Its main components are chromium, nickel, silicon, nitrogen, etc. ZG40Cr25Ni20Si2 is a high-temperature alloy material suitable for working environments with high temperatures above 1100°C. At the same time, it also has good mechanical properties and thermal fatigue resistance, which can meet the requirements of working with heavy loads at high temperatures. To ensure the quality and service life of the material, the kiln mouth guard plate is usually produced by the vacuum negative pressure die casting process. This process can effectively reduce the porosity and the number of inclusions in the material, as well as improve the density and mechanical properties of the material.

The rotary kiln guard plates and heat-resistant steel chains produced by Zhili New Materials are preferred by the cement industry. We have a professional team, product quality guarantee and impeccable after-sales service. We also offer product export services.

Related articles

The Dragon Boat Festival, also known as the Duan Yang Festival and the Dragon Boat Festival, is one of the four major traditi...

Chutes are widely used in bulk material transport and storage systems. They play an important role in coal mining, connecting...

The ceramic composite crusher hammer primarily utilizes high-chromium cast iron and other wear-resistant alloy materials. The...

The main components of impact crushers include impact bars, impact plates, rotor, square steel, impact liner bolts, hinged co...

The manufacturing process of the wear-resistant tubular wire coating roller directly affects the wear resistance, bond streng...

We supply spare parts for hammer crushers, jaw crushers, cone crushers, impact crushers, and vertical mills. As an industry-l...