I will share with you professionally and help you choose the right hammer to reduce hammer wear. Increase your factory‘s productivity.Of course, not just the crusher hammer head, impact bar, jaw plate, mantle and concave, vertical mill, lining and Hardox steel. I will share everything with you in full....

Luoyang Zhili New Materials, established in 1992, is one of the leading processing centers for wear-resistant materials in the world, providing high-quality service for wear parts in the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

I share with you professionally and help you choose the right hammer to reduce wear and increase the productivity of your factory.

Of course, not only the crusher hammer head, impact bar, jaw plate, mantle and concave, vertical milling cutter, coating and Hardox steel. I will share it with you completely. ...

4. It increases the cost of labor for workers. Very rapid wear and tear causes workers to replace parts frequently.

The reasons for the above problems are complex and can be divided into the following types:

1. Quality problems caused by production.

During the production process, the manufacturer did not perform good quality control and the heat treatment technology was not sufficiently developed, resulting in voids, cracks, and excessive sand adhesion to the hammer head.

2. Choosing the wrong material to apply under unsuitable working conditions.

Different materials have different hardnesses, but we cannot simply seek hardness, as hardness is inversely proportional to toughness; if the hardness is too high, the hammer may break easily during work. We can only find a balance between hardness and toughness so that the hammer achieves the greatest advantages of the materials under the corresponding working conditions.

Besides choosing a factory with more advanced production technology and quality control, I think you can also learn about the different materials to choose from.

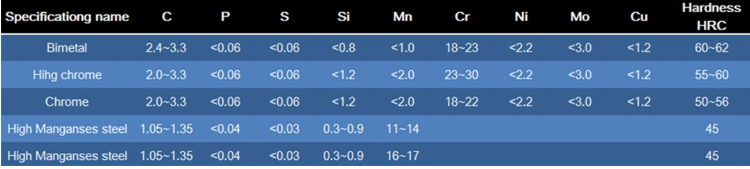

Until next time, I will share with you the differences between the materials.

Related articles

We will strive to achieve greater advancements as quickly as possible and produce higher quality, more wear-resistant product...

Maintaining and preserving the clinker conveyor chain in a cement plant is very important, as it is related to the stable ope...

During the operation of the OK mill (vertical mill), due to direct contact with materials, high pressure, high temperature, a...

The main components of impact crushers include impact bars, impact plates, rotor, square steel, impact liner bolts, hinged co...

The high-manganese steel crushing hammer has good toughness, good manufacturability, and high safety performance. Its main ch...

Furthermore, the hot air and cement particles will continuously scrape the contact surface, resulting in the formation of gro...