Furthermore, the hot air and cement particles will continuously scrape the contact surface, resulting in the formation of grooves, causing impact and collision between the car body and the coating....

Luoyang Zhili New Materials, established in 1992, is one of the leading processing centers for wear-resistant materials in the world, providing high-quality service for wear parts in the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

Operating principle of the vertical mill:

The motor of the vertical mill drives the grinding disc to rotate through the reducer. At the same time, hot air enters the vertical mill through the air inlet. The material falls into the center of the grinding disc from the discharge port. Due to centrifugal force, the material moves from the center of the grinding disc to the edge of the disc. As it passes through the annular groove of the grinding disc, it is crushed by the grinding roller. The crushed material continues to move to the edge of the grinding disc until it is carried by the airflow in the winding ring, and the larger particles fall onto the grinding disc and continue to be crushed.

When the material in the airflow passes through the upper separator, under the action of the guide blades, the coarse material falls from the conical bucket onto the grinding disc, and the fine powder is discharged from the mill along with the airflow and collected by the system's dust collector. The collected powder is the product of the vertical mill. The material is dried in the process by contact with the gas in the casing to achieve the necessary dryness and moisture content of the product. By adjusting the angle of the separator's guide blade (the small vertical mill cannot be adjusted) and the speed of the separator rotor, it is possible to achieve the required coarseness and fineness of the product.

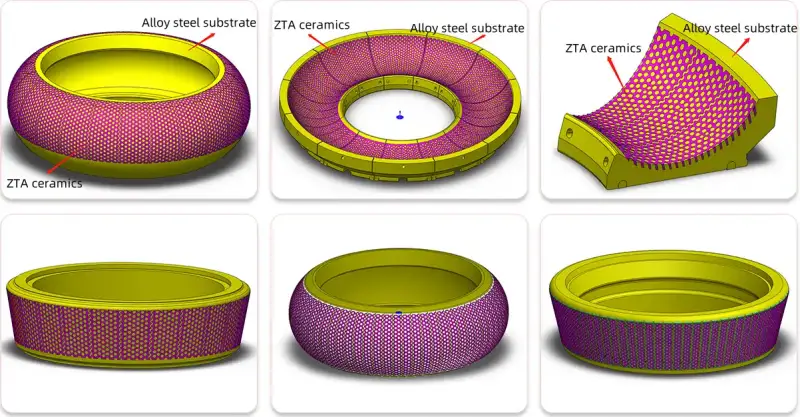

Through the operating principle of the vertical mill, we discovered that the vertical mill roller is the central part of the mill. To improve the wear resistance of the machine, the roller needs to have sufficient toughness and good wear resistance. During the use of the vertical mill roller body and the wear-resistant liner, once there is a gap in the fitting, the wear between the body and the liner will be aggravated. In addition, hot air and cement particles constantly scrape the fitting surface, resulting in the formation of grooves, causing impact and collision between the body and the liner. In severe cases, the coating can crack or even break, and the machine can be damaged, especially the reducer, causing dangerous incidents. When such problems occur, general repair methods are difficult to resolve, and the replacement cost is high. Zhili New Materials is a company specializing in mill roll accessories. It has extensive experience and has produced several wear-resistant solutions for roll production. The service life of our rolls is three times longer than that of other companies, which is widely proven in the industry. Our roll base is made of high-strength alloy steel, and wear-resistant pins can also be added. The roll surface can be welded with welding wire, and ceramic can be added to improve the product's wear resistance.

Regularly perform paving, oil changes, and other maintenance operations on the vertical cement mill to reduce the possibility of equipment failures and avoid affecting the normal production of the project. Especially for complex machines and equipment, any problem with any component can cause equipment failures and prevent its normal operation. How to improve the performance of vertical mills is a difficult problem faced by all companies. We can provide companies with wear-resistant solutions. If you are interested, please contact us.

Related articles

Zhili New Materials Company primarily manufactures crusher accessories, such as hammer heads, impact bars, rotors, liners, an...

Our company independently develops a series of hard alloy surface products that can effectively extend the service life of we...

The client ordered a batch of link products earlier this year, and the usage has been positive. This visit is primarily aimed...

On the eve of the Spring Festival, all families are immersed in a bustling and joyful atmosphere. Cleaning is an indispensabl...

During the use of a ball mill, the selection of the grinding medium is crucial. The grinding medium is affected by several fa...

In response to customers' desire to improve the production and lifespan of impact bars, our company provides two solutions th...