During the use of a ball mill, the selection of the grinding medium is crucial. The grinding medium is affected by several factors, such as material, charge, shape, particle size, etc....

Luoyang Zhili New Materials, established in 1992, is one of the leading processing centers for wear-resistant materials in the world, providing high-quality service for wear parts in the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

During the use of a ball mill, the selection of the grinding media is crucial. The grinding media is affected by many factors, such as material, charge, shape, particle size, etc. In the grinding process, different grinding media are used for different materials, models, and equipment in order to reduce production costs and improve production efficiency.

Density, hardness, and size of the media

The higher the density of the grinding media, the shorter the grinding time. To increase the grinding effect, the hardness of the grinding medium should be greater than the hardness of the material to be ground. Ideally, the Mohs hardness of the medium should be 3 levels higher than the hardness of the material to be ground, and the effect is more evident. In addition, the smaller the size of the grinding medium, the more points of contact there will be with the medium and the more opportunities there will be to grind the material.

Amount of Filling Media

The amount of filling has a direct impact on grinding efficiency, and the particle size of the grinding media determines the amount of filling media. It must be ensured that the void ratio of the grinding media is not less than 40% when the grinding media moves in the disperser. For different fineness requirements, it is necessary to adjust the grinding and grinding capacity distribution of the grinding media. The higher the filling ratio, the greater the grinding capacity and vice versa, the greater the crushing capacity. In ultrafine grinding, a high filling ratio is generally used.

Material

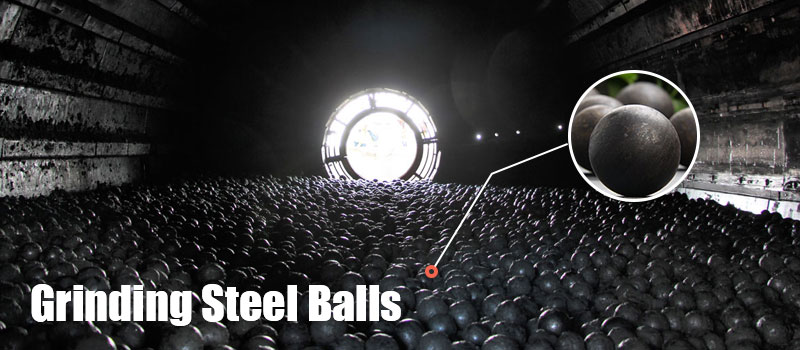

The grinding material determines the cost and efficiency of crushing. Grinding materials can be mainly divided into three categories: metallic media, rock and mineral materials, and non-metallic materials. In addition to considering the cost of production, the selection should also consider whether the material and the medium will cause pollution. Commonly used grinding media include steel balls, aluminum oxide balls, tungsten carbide balls, zirconium oxide balls, etc. Steel balls have high density and high efficiency in grinding materials. They are suitable for wet and dry grinding processes. Ceramic spheres are commonly used in ball mills for grinding ceramic raw materials, pigments, and ceramic feldspar. Ceramic spheres are made of high-quality ceramic and exhibit excellent wear resistance. They are suitable for both wet and dry grinding. Tungsten carbide spheres are commonly used in high-energy ball mills. Tungsten carbide spheres are extremely hard and can withstand large impact forces. Tungsten carbide spheres are ideal for grinding hard and brittle materials such as metals, alloys, ceramics, and minerals. Zirconia spheres are another grinding media used in ball mills. They are made of zirconium oxide and exhibit high density and wear resistance. Zirconia spheres are suitable for materials requiring high-purity, pollution-free grinding. Grinding media are generally spherical because other irregularly shaped media wear out and cause unnecessary pollution.

Format and size

The size of the medium directly affects grinding efficiency and product fineness. The larger the diameter, the larger the product particle size and the higher the production; conversely, the smaller the medium particle size, the smaller the product particle size and the lower the production. In actual production, it is usually determined according to the feed particle size and product fineness.

Medium Ratio

In continuous grinding processes, the size of the grinding media is distributed in a specific pattern, and the media size ratio is directly related to grinding capacity and energy consumption. In this process, a fixed media ratio will not be maintained at all times. In production, the method of supplementing with large spheres is often used to restore the system's grinding. It is difficult for the mill to maintain a fixed media ratio for a long time. When the difference in media diameter is too large, it exacerbates inefficient grinding between media and increases costs.

Wear Resistance and Chemical Stability

The wear resistance and chemical stability of grinding media are important conditions for measuring the quality of grinding media. Media that are not wear-resistant need to be continuously replenished due to wear, which will not only increase costs but also affect production. Grinding media need to have a certain chemical stability in a specific grinding process and cannot chemically react with the material during grinding, contaminating it.

Companies should choose appropriate grinding media according to their working conditions and machines. Zhili New Materials can produce various spheres for grinding media. Companies that need to meet their requirements simply need to have the appropriate grinding media supplied, and we will provide the suitable grinding media to increase production capacity.

Related articles

We have advanced production equipment and R&D teams, as well as over 30 years of experience in producing wear-resistant a...

We supply spare parts for hammer crushers, jaw crushers, cone crushers, impact crushers, and vertical mills. As an industry-l...

Our optional materials for jaw plates: high manganese steel, super high manganese steel, alloy steel, titanium alloy bars wit...

Hammer crushers, impact bars, linings, etc., are products that our company has been manufacturing for a long time, and their ...

We supply spare parts for hammer crushers, jaw crushers, cone crushers, impact crushers, and vertical mills. As an industry-l...

The ceramic composite crusher hammer primarily utilizes high-chromium cast iron and other wear-resistant alloy materials. The...