The material of the cast pin roller column nail is titanium carbide (TiC), not tungsten carbide (WC), and the column nail cannot be replaced....

Luoyang Zhili New Materials, established in 1992, is one of the leading processing centers for wear-resistant materials in the world, providing high-quality service for wear parts in the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

Around 2008, roller presses began to be used in ore production lines to press materials such as iron ore. Because the strength and hardness of materials like iron ore are far superior to those of limestone, clinker, and other materials in the cement industry, the traditional brazing and alloy rollers used in the mining industry could no longer meet production needs. In 2009, stud rollers embedded with hard tungsten carbide alloy studs began to be used in the mining industry and yielded good results. They were gradually used in cement roller presses after 2012.

With the increasing application of pin rollers, various roller manufacturers present differences and variations in the production and manufacturing process of pin rollers. For example, the selection of column nail diameters is different, including 16 mm, 20 mm, 22 mm, etc. The combination of column nails and substrates includes adhesive fastening, interference fit mounting, direct casting, etc.

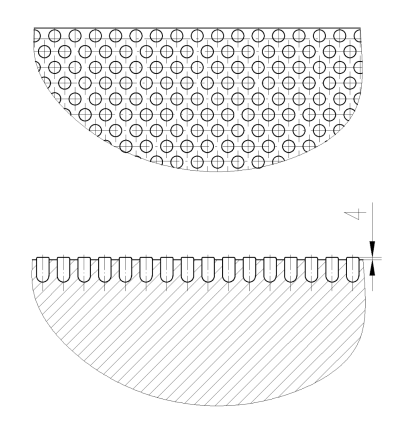

1. Structure and manufacturing method of traditional pin rollers

A hole for installing the column nail, corresponding to the size of the column nail, is drilled in the outer circle of the roller sleeve using a special drilling and milling machine. Anaerobic adhesive is used to glue the column nails into the hole in the base, and the head of the column nail is exposed approximately 4 mm from the surface of the base. Some manufacturers use interference fit to press the post nails into the installation holes.

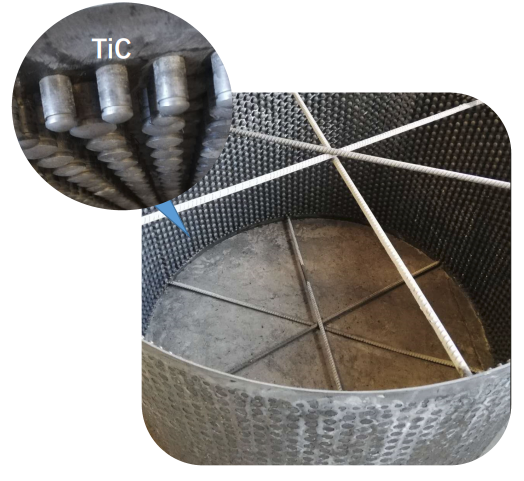

2. The structure and manufacturing method of the cast roller pin

The material of the cast roller column pin is titanium carbide (TiC), not tungsten carbide (WC), and the column pin cannot be replaced.

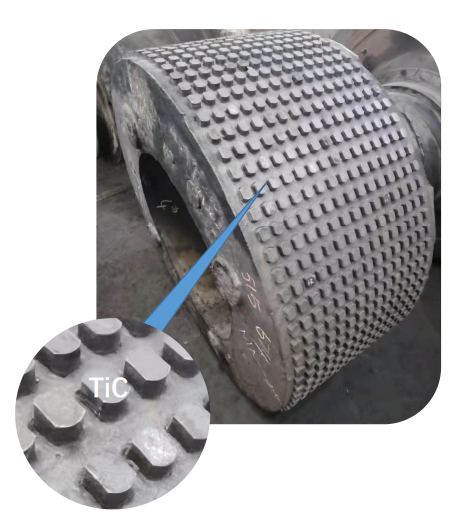

3. Structure and manufacturing method of the pressure pin pressure roller

The cast pressure roller is made by casting long strips of titanium carbide onto the base material of the roller sleeve and then applying wear-resistant materials around the titanium carbide.

Related articles

We supply spare parts for hammer crushers, jaw crushers, cone crushers, impact crushers, and vertical mills. As an industry-l...

The Dragon Boat Festival, also known as the Duan Yang Festival and the Dragon Boat Festival, is one of the four major traditi...

Wear-resistant ceramic metal composite material is a type of casting infiltration technology used to evenly distribute cermet...

Siping Hongzui Cement Co., Ltd. is a key company of the Hongkou Group, a large small-scale enterprise in China. It is a major...

Stability is obviously much better. Most importantly, the operating rate of the roller press has been improved and maintenanc...

We supply spare parts for hammer crushers, jaw crushers, cone crushers, impact crushers, and vertical mills. As an industry-l...