Stability is obviously much better. Most importantly, the operating rate of the roller press has been improved and maintenance costs have been reduced....

Luoyang Zhili New Materials, established in 1992, is one of the leading processing centers for wear-resistant materials in the world, providing high-quality service for wear parts in the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

The two most critical devices in the current combined grinding system with roller press are the roller press and the ball mill. The proper or improper functioning of the roller press directly affects the stability of the entire system, including the volume and cost of production. This phenomenon is particularly evident in the recently popular combined semi-final grinding system.

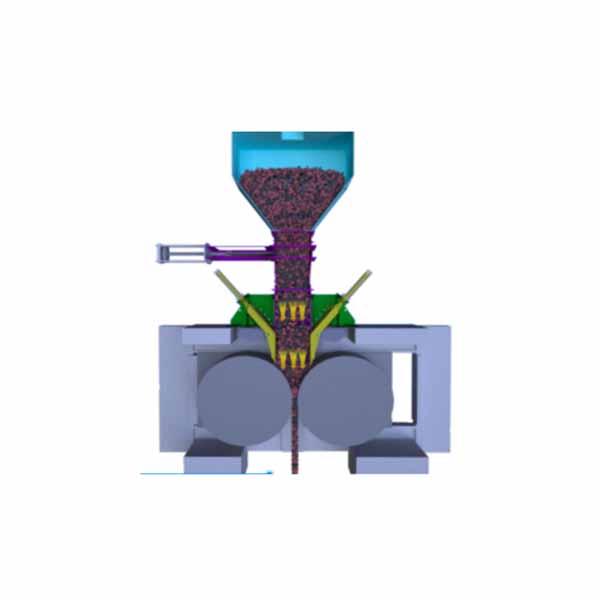

There are many problems with the current roller press feed device. For example, the flow in a roller press cannot be controlled by the central control operator, and the manual gate valve can only be adjusted by on-site personnel to adjust the flow rate. The manual feed gate valve for roller presses on-site frequently jams due to ash ingress and forced deformation, making adjustment impossible and resulting in the valve becoming unusable on-site. Some manufacturers use an electrically adjustable gate valve, and the threaded rod also jams or even breaks. In response to these problems, and drawing on our years of experience, our company has developed an efficient double slide feed device. We adopted a unique design for the side deflector, which ensures an accuracy of approximately 1 mm in the side deflector clearance, significantly reducing material leakage at the roller edge and system energy consumption caused by inefficient circulation. This also solves the dust emission problem of the old feeding device and improves the working environment on site. The independent hydraulic system of the feeding device has precise and reliable hydraulic transmission, adjustable opening and closing speed of the flow regulating plate, and is maintenance-free. This solves the problem of equipment damage caused by dust accumulation and screw jamming. The feeding device not only presents its absolute advantage in the cement grinding system, but also performs very well in the final grinding of raw materials.

After replacing this new feeding device, the operation of the roller press was significantly improved, the circulating load was reduced, the winch current was reduced, and there is no need to worry about the winch crushing. The stability is obviously much better. Most importantly, the operating rate of the roller press was improved and the maintenance cost was reduced.

Related articles

Without the return cone, the raw flour filaments would simply slide down the inner wall of the tube like dense "noodles&...

On the eve of the Spring Festival, all families are immersed in a bustling and joyful atmosphere. Cleaning is an indispensabl...

We will be showcasing our newly developed, independently developed products, such as heat-resistant steel chains, furnace pro...

Zhili New Materials will participate in the FICEM 2024 Technical Conference, held in Glenbia from September 16-18, 2024. We m...

Our company independently develops a series of hard alloy surface products that can effectively extend the service life of we...

Wear-resistant ceramic metal composite material is a type of casting infiltration technology used to evenly distribute cermet...