The customer expressed great appreciation for our long-standing supply of products, including crusher hammers, grates, ball mill end liners, and preheater supports....

Luoyang Zhili New Materials, founded in 1992, is one of the world's leading processing centers for wear-resistant materials, providing high-quality wear parts services to the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

Recently, a maintenance manager from a renowned cement plant in Sri Lanka visited our company. Both parties discussed in depth the achievements of previous collaboration and potential future opportunities. Our business manager, Ms. Gloria, and her team warmly welcomed the client and accompanied him in the conversation.

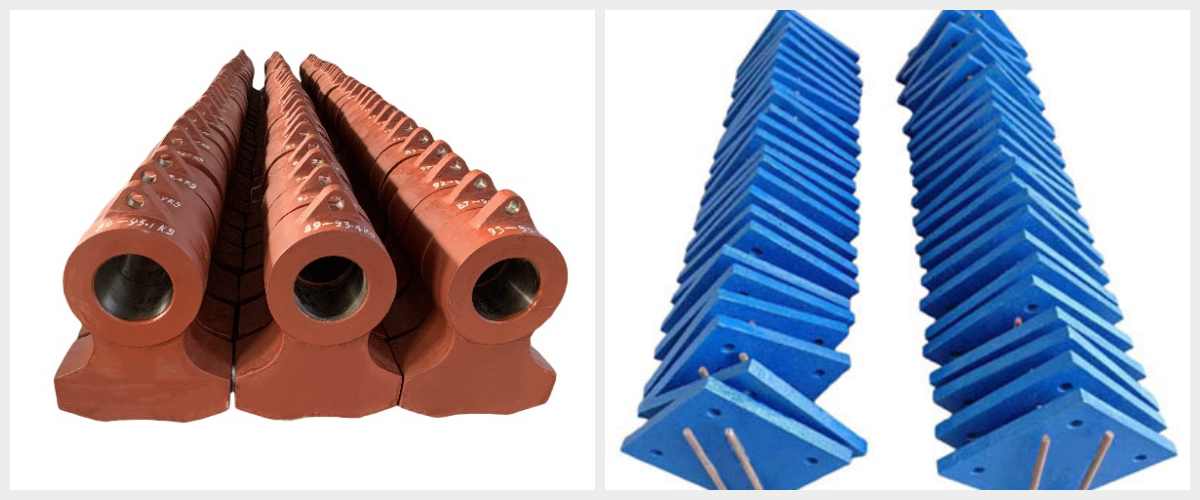

During the meeting, Gloria gave the client a detailed introduction to our company's history, technical strengths, and main products, emphasizing our strengths in R&D and our ability to manufacture wear-resistant materials. The client expressed great appreciation for our long-standing supply of products, including crusher hammers, grates, ball mill end liners, and preheater supports. They particularly praised the high quality and punctuality in the delivery of the hammers and expressed satisfaction with our service.

Based on the excellent partnership and user feedback, the client expressed a clear desire to expand cooperation, especially in the areas of ball mill linings and grinding balls. The cement plant currently operates four ball mills, including two raw material mills and two cement mills, and has shown great interest in our linings and grinding balls.

Based on the client's needs, Gloria specifically recommended our Aubey grinding balls. This product maintains the same high hardness and wear resistance as high-chromium balls, but offers superior economic efficiency and a significant cost-benefit ratio. Its ball breakage rate is less than 1%, and its performance is stable and reliable. The customer highly praised this product and initially agreed to conduct a 60-ton test. Once the results are verified in real-world use, they will actively seek a larger volume purchase.

This meeting further solidified the partnership of trust between the two parties and established a solid foundation for future market expansion. Our company will continue to focus on customer needs, continuously improving product performance and service quality, and providing customers with comprehensive and more competitive solutions.

Related articles

The customer expressed great appreciation for our long-standing supply of products, including crusher hammers, grates, ball m...

Our technology has developed a new stu+ coating roller, whose base is made of high-strength alloy steel and studs. The presen...

In 2023, a cement factory in Qatar ordered a set of limestone crusher hammers from our factory. The material is high-manganes...

1. Performance characteristics of the ceramic-metal composite vertical mill roll; 2. Performance characteristics and structur...

They learned mainly about the jaw plate, side guard plate, toggle plate, eccentric shaft, and other accessories related to th...

They ordered standard hammers made of high-manganese steel from us. They also discovered that they had to contact several com...