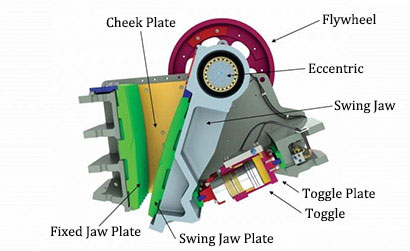

In sand and gravel production, the jaw crusher is a relatively common crushing equipment, consisting of a frame, jaw plate and side protection plate, transmission parts, adjustment device, flywheel, lubrication device, etc. Here, we will briefly present the six main components of the jaw crusher....

Luoyang Zhili New Materials, established in 1992, is one of the leading processing centers for wear-resistant materials in the world, providing high-quality service for wear parts in the mining, cement, power plant, steel, coal, and other industries.

Zhili New Materials

In sand and gravel production, the jaw crusher is a relatively common crushing equipment, consisting of a frame, jaw plate and side protection plate, transmission parts, adjustment device, flywheel, lubrication device, etc. Here, we will briefly introduce the six main components of the jaw crusher.

1. Structure

The structure is a rigid structure with four open walls at the top and bottom. Its function is to support an eccentric shaft and withstand the reaction of the crushed material. It needs to have a certain strength and rigidity. It is usually cast as a whole with cast steel. For small machines, it can also be replaced by high-quality cast iron. The structure of large machines is generally cast in blocks and fastened with bolts. The casting process is relatively complex. The structure of the small jaw crusher, developed by ourselves, can also be welded with steel plate of a certain thickness, but its rigidity is not high.

2. Jaw Fixing and Structure

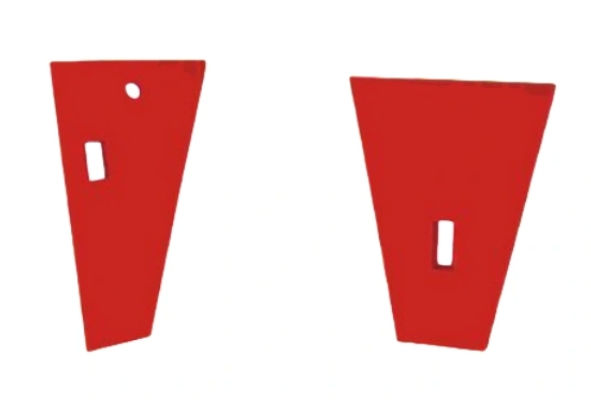

Fixed and movable jaws are composed of two parts: the jaw seat and the jaw plate. The jaw plate is the functional part and is connected to the jaw seat by screws, iron wedges, etc. The jaw seat of the fixed jaw is the front wall of the structure, and the movable jaw is suspended on the circumference. It needs to have a certain hardness and strength to withstand the reaction force during crushing, therefore, cast steel or cast iron are the most commonly used.

Jaw crusher parts produced by our company

3. Drive Parts

The eccentric shaft is the main shaft of the crusher, which is subject to large bends and twists. The inner bearing bushing is cast from babbitt alloy and surface treated. A pulley is installed at one end of the eccentric shaft and a flywheel at the other end.

4. Adjuster

The adjustment mechanism can be wedge-shaped, cushion-shaped, hydraulic, etc. The wedge-shaped structure is generally used, consisting of two wedge-shaped structures: the front wedge structure can move forward and backward to press the rear; the rear wedge is an adjustment wedge that can move up and down. The inclination of the two wedges is reversed, and the screw drives the rear wedge to move up and down to adjust the discharge size. The small jaw crusher adjusts the discharge by increasing or decreasing the number of spacers between the backing plate support and the frame.

5. Rotating Flywheel

The flywheel of the jaw crusher is used to store the energy generated by the movement of the moving jaw, which is then used for industrial shaping, making the machine's work more consistent. The pulley also acts as a flywheel. The flywheel material is usually cast iron or steel, and it is a single piece in small machines. When manufacturing and installing the flywheel, attention must be paid to its static balance.

6. Lubrication Mechanism

The eccentric shaft bearings are usually lubricated by central circulation. The bearing surfaces of the main shaft and backing plate are usually lubricated with grease applied by a hand-held oil gun. Because the angle of rotation of the moving nozzle is small, it is difficult to lubricate the main shaft and the bearing sleeve. Typically, several axial oil grooves are carved into the bottom of the bearing sleeve, and an annular oil groove is carved in the center to connect the two bearing sleeves. Then, an oil pump is used to force dry butter to lubricate the bearing sleeve.

Jaw crusher parts produced by our company

Related articles

In the morning, the company office was immersed in a festive and cheerful atmosphere, and the benefits distribution area was ...

Our company independently develops a series of hard alloy surface products that can effectively extend the service life of we...

We supply spare parts for hammer crushers, jaw crushers, cone crushers, impact crushers, and vertical mills. As an industry-l...

Bimetallic hammer for customer, hammer hammers, coal crusher hammer, clinker crusher hammer, crusher hammer for sale, high ma...

Guangzhou quarry exhibition, wear parts for impact crushers, wear parts for crushers, crushing parts, impact bars, price of i...

Hammer crushers, impact bars, linings, etc., are products that our company has been manufacturing for a long time, and their ...